The rise of Artificial Intelligence (AI) and Machine Learning (ML) is transforming the landscape of electronics testing. Across the globe, electronics companies are under pressure to launch ever more sophisticated products at breakneck speed, all while upholding strict quality standards. Today’s system-on-chip (SoC) designs can pack in billions of transistors and a tangle of complex firmware, making comprehensive testing a daunting challenge. Traditional approaches—relying on preset test vectors and deterministic algorithms—are often outpaced by the sheer scale and complexity. Now, AI and ML are stepping into the spotlight, promising to revolutionise autonomous testing. By applying probabilistic reasoning, pattern recognition, and adaptive algorithms, these technologies are saving weeks of development cycles and boosting defect detection rates by as much as 25-40 percent, according to industry insiders.

AI Efficiency vs. Manual Testing

The story of testing in electronics has a quirky beginning: in 1945, engineers traced a malfunction to a real, fluttering moth inside a computer relay. Fast-forward a decade, and testing had become a specialised discipline. Yet, even as methods grew more sophisticated, manual testing remained laborious, vulnerable to human oversight, and often unable to keep pace with the demands of modern design. Enter a new era, where technology, not tradition, leads the charge, and the boundaries between human and machine blur in pursuit of precision.

Challenges in AI/ML for Testing

While there is no doubt that integration of AI and ML offers pace to the testing procedure, the real problem comes down to determining how much data is needed to feed the AI for thorough and accurate testing, mainly for start-ups and small teams.

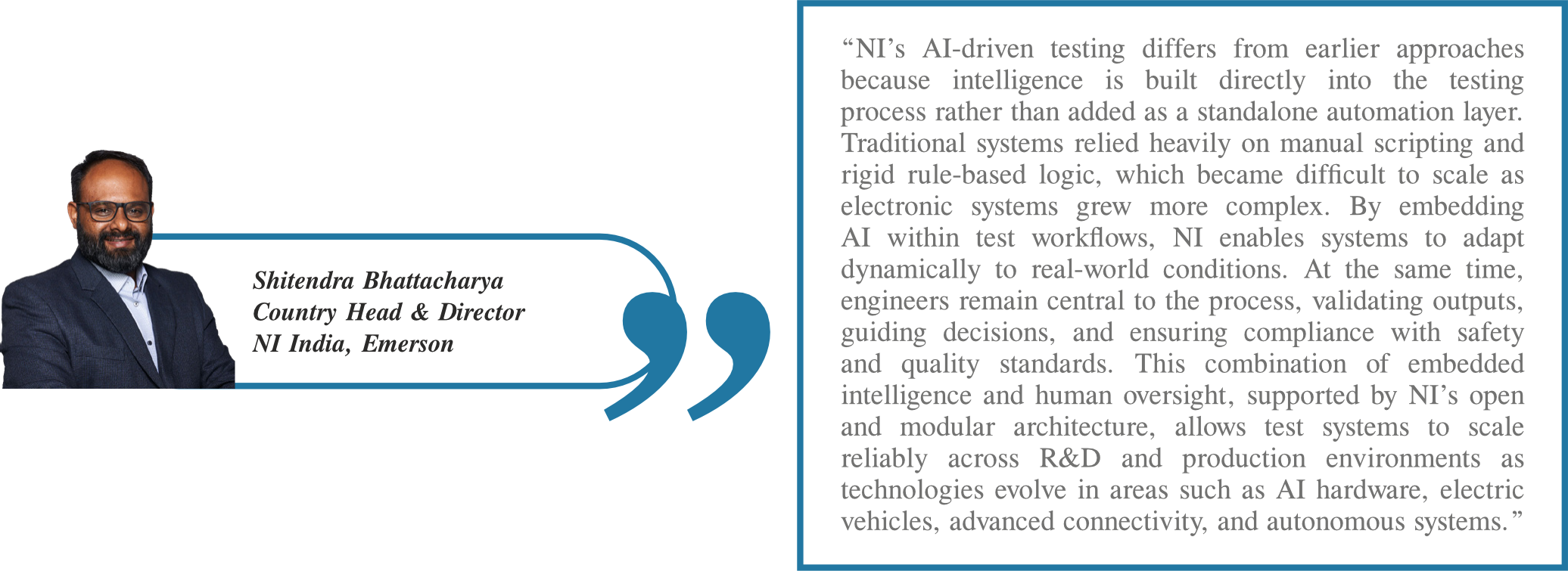

“One of the primary challenges in developing AI-driven test systems is ensuring high-quality, unbiased data, as AI models depend heavily on reliable inputs. Maintaining transparency in AI-driven decisions and balancing automation with human expertise are also critical, particularly in regulated and safety-sensitive industries. NI addresses these challenges through its open, software-defined test architecture and engineer-led AI integration. By standardising data acquisition and validation at the source, NI ensures data consistency, traceability, and transparency before AI is applied. This same foundation enables efficient integration with emerging IoT technologies, as modular hardware and open software can easily connect with diverse sensors, devices, and communication protocols. Edge computing capabilities further support real-time data processing closer to IoT endpoints, reducing latency and improving responsiveness as IoT systems continue to evolve,” says Shitendra Bhattacharya, Country Head & Director, NI India, Emerson.

The “Black Box” issue is considered one of the most core challenges in the incorporation of AI in autonomous testing. It refers to the difficulty in understanding how complex models, especially deep learning systems, reach their decisions, treating them like opaque boxes with only inputs and outputs visible, leading to issues with trust, fairness, accountability, and debugging, as their intricate, multi-layered processes are hard to interpret, potentially hiding bias or errors.

“Each step of the way, decisions need to be made on parameters to optimise. The goal is to test as much as possible with as few test patterns as possible to manage costs,” explained Fadi Maamari, vice president of engineering for hardware analytics and test, Synopsys

Benefits of AI in Testing Solutions

“AI is already making a big impact in adaptive test optimisation and anomaly detection,” said Eduardo Estima de Castro, senior manager of R&D engineering at Synopsys. “Machine learning helps prioritise high-value test patterns, cut test time, and identify systemic yield issues. It also enables real-time adjustments to test limits, improving outgoing quality. These capabilities bring significant efficiency gains in high-volume production.”

AI has the capability to generate an extensive range of real-world scenarios for testing. The extensive range helps reduce the possibility of error and gives engineers a wider scope for creativity.

NLP-driven technologies analyse requirements and user stories to produce test cases that meet defined criteria. This approach guarantees full test coverage while reducing the manual labour required to create test cases. Additionally, AI and machine learning algorithms may prioritise test cases based on risk, criticality, and defect history. This prioritisation guarantees that the most critical tests are run first, hence optimising testing efforts and increasing coverage. AI-powered technologies may also do root cause analysis, identifying the underlying causes of faults and making meaningful recommendations for remediation. AI and ML technologies automate visual testing by comparing application aspects (e.g., UI components) to predicted results. The best feature is their ability to continuously learn from fresh data and adapt to changing requirements. This continual learning increases the accuracy and efficacy of test automation technologies, resulting in continued improvements to software testing.

Core Technology Involved

While different AI models are designed differently, throwing light on the core functioning of this concept, Shitendra Bhattacharya, Country Head & Director, NI India, Emerson said, “The foundation of this testing software is a software-defined, modular test architecture combined with AI-driven data intelligence. This design enables autonomous test systems that can adapt to changing requirements, learn from data, and improve performance over time. Open test software platforms such as NI LabVIEW, TestStand, SystemLink, and FlexLogger allow engineers to design, customise, and reuse test logic across products and industries while integrating seamlessly with third-party tools, cloud platforms, and emerging technologies. This is complemented by modular, software-connected hardware, including PXI, CompactDAQ, CompactRIO, and USRP, which decouples hardware from software logic, allowing systems to be upgraded or repurposed through software alone. An AI-ready data architecture further embeds analytics directly into the testing workflow, enabling real-time data collection, automated structuring, and intelligent analysis to detect patterns, predict failures, and flag anomalies early.”

Adoption Rate and Use Cases

AI is widely used to test software embedded in electrical devices, which falls under the wider umbrella of AI in software testing. The key areas of adoption include:

Self-healing tests: AI systems detect changes in the application’s UI or code and automatically update test scripts, eliminating the need for maintenance.

Test case and data generation: AI can create broad and realistic test data and scenarios based on user stories and historical data, including edge situations that human testers may overlook.

Predictive analytics: Artificial intelligence analyses past data to anticipate where problems are most likely to arise, allowing QA teams to focus testing on high-risk regions.

“Adoption of AI-enabled and autonomous testing is already accelerating, particularly in industries experiencing rapid growth in electronic complexity, including semiconductors, automotive and EVs, aerospace and defence, and advanced manufacturing. Today, adoption is most visible in R&D and validation environments, where AI helps analyse large test datasets, and in high-volume production testing, where automation improves speed, consistency, and yield. Looking ahead, AI-driven testing is expected to become the norm as systems become too complex for manual approaches. This shift will enable faster time-to-market, improve product reliability, and allow engineers to focus more on innovation and system-level problem-solving rather than repetitive test tasks,” explains Shitendra Bhattacharya, Country Head & Director, NI India, Emerson.

Manufacturers use AI-powered computer vision systems to inspect electronic components like PCBs for defects such as misaligned components, micro-cracks, and solder joint faults. These systems can identify anomalies with high accuracy and speed that are difficult for human inspectors or traditional camera systems to catch, leading to zero-defect manufacturing goals.

Agilent used AI vision tools to reduce defect rates by 49% in four months in one application. Companies like Jidoka and Averroes provide specific AI tools for PCB inspection that integrate with existing manufacturing lines and learn new defect types from minimal sample images.

What the Future Holds?

The future of AI and ML in test automation is bright, with continued advancements set to further revolutionise testing in the electronics industry. Here are some emerging trends to watch:

- Autonomous Testing: The ultimate goal of AI and ML in test automation is to achieve autonomous testing, where the entire testing process, from test case generation to execution and analysis, is fully automated with minimal human intervention. While this level of autonomy is still developing, ongoing advancements are bringing it closer to reality.

- Enhanced Collaboration: AI and ML are bound to drive better collaboration between development, QA, and operations teams by providing actionable insights and predictive analytics. These insights will allow teams to make informed decisions, refine testing strategies, and enhance overall software quality.

- Integration with Emerging Technologies: AI and ML will increasingly integrate with other emerging technologies such as the Internet of Things (IoT), blockchain, and edge computing. This integration will enable holistic testing of complex, interconnected systems, ensuring their reliability and performance in real-world scenarios.

• Continuous Learning and Improvement: AI and ML models will continue to evolve, learning from new data and adapting to changing requirements. This continuous learning will enhance the accuracy and effectiveness of test automation tools, driving ongoing improvements in software testing.

By: Shreya Bansal, Sub-Editor