With improvements in AI and IoT visualizing the factories of the future can be truly magical for tech enthusiasts. The implementation of several significant advances and practices in science and technology will undoubtedly revolutionize the electronic manufacturing sector.

Facilities will be highly automated, and sustainability will be emphasized, but the technology and trends influencing electronics production aim to support, not replace human ingenuity.

Augmented/virtual reality (AR/VR), the Internet of Things (IoT) and Industrial IoT (IIoT), as well as artificial intelligence (AI), all help manufacturing operations advance while lowering costs and making workplaces safer for employees. Environmentally friendly manufacturing practices will be emphasized in both products and facilities, as well as cyber and physical security.

AR/VR in electronic manufacturing

AR/VR offers a degree of interaction between people and machines that combines the imaginative with the useful. VR and AR are used by engineers to improve and optimize designs early on. Ideas and solutions can be readily evaluated, tweaked, and changed. It is also possible to virtually test, analyze, and simulate digital models. Rapid iterative design cycles are the outcome.

Animated and computer simulations are also made possible by VR and AR, enabling designers to envision how goods will be utilized over time and take into account elements like ergonomics, access, look, and feel. In order to communicate with customers, manufacturers also employ tools like lifelike simulations because 2D drawings or 3D models cannot replicate the experience of a lifelike simulation. In the end, VR and AR help with collaboration and purchase during the product creation process. As a result, there is less technical risk and a higher likelihood that the components and products will be fit for their intended use. India too is moving towards a more technologically advanced electronic manufacturing setting.

IoT, IIoT, and Automation

Further analysis of this data yields knowledge that may be applied to improve the manufacturing process.Microsoft and consumer products company Procter & Gamble launched a significant digital partnership earlier this year. The P&G team will access real-time data and AI models through Microsoft’s digital manufacturing system, which will assist improve and expedite production.

AI-based preventive maintenance

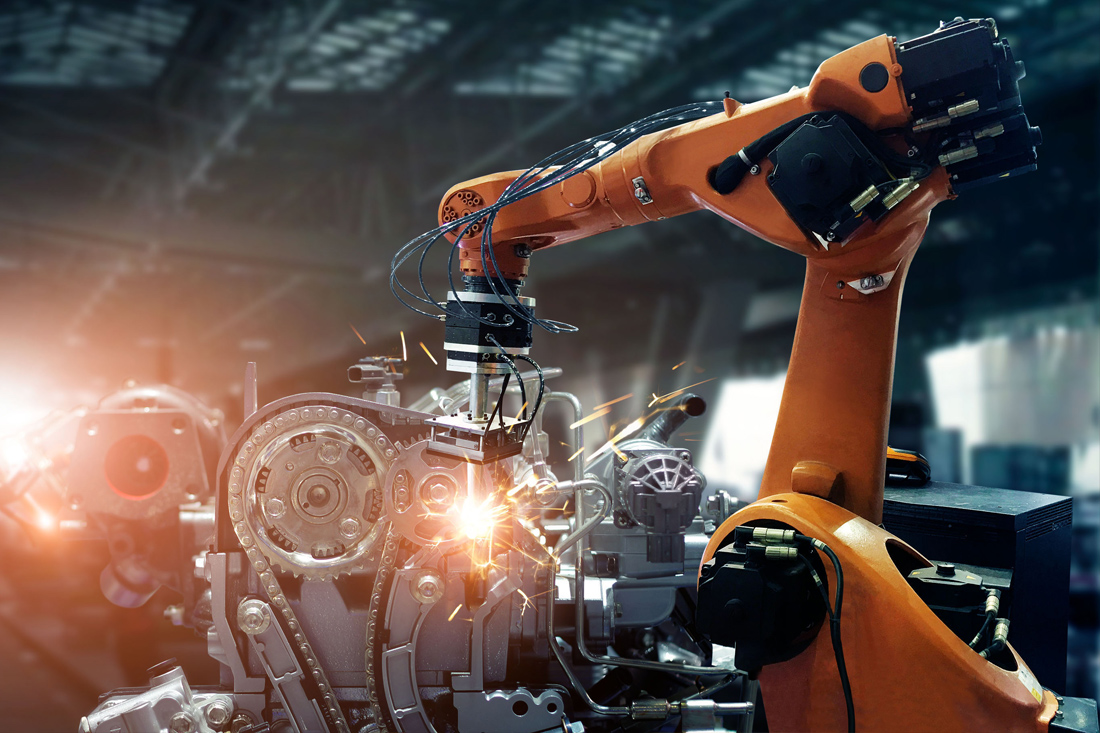

Using AI in manufacturing entails using data to arrive at judgments that can be taken immediately and with greater accuracy than a human. It is the underpinning technology for predictive maintenance, which, based on prior experience, predicts how a machine will react under a future burden and when, why, and how it needs to be fixed.

Sensors, which offer information on electrical flow, vibration, temperature, and a range of other metrics that can affect a machine’s performance, are a key component of these systems. Early preventative maintenance strategies warned individuals about issues with specific equipment; today, they can pinpoint which component caused a notification. Artificial intelligence (AI) has a role in quality, scrap reduction, and inventory/demand forecasting, while predictive maintenance lowers plant downtime and associated expenses.

It is possible to reduce waste and improve product quality by using measurements to predict behavior across product requirements. Manufacturers can proactively take the necessary steps to bring a machine or process back into compliance by anticipating when it will no longer meet certain requirements, or drift.

Cyber, virtual and material protection

Manufacturing facilities are becoming more networked. They contain intelligent machines that gather information and display insightful trends. Collaborative robots that increase productivity alongside humans are present in some workplaces. Additionally, producers might use automated systems that enable prompt reordering of goods before they run out of stock.