Introduction

Silicon has been the primary driver of the computing growth for decades, but Moore’s Law is now reaching its limits. As the need for chips to be faster and more energy-efficient grows, the pressure on supply chains are like never before due to shortages and geopolitical tensions.

This is where AI and quantum computing come into play. It is not science fiction; they are helping discover new semiconductor materials and optimizing production scheduling in wafer fabs. This results in shorter lead times, reduced risks, and a more resilient supply chain.

For engineers and procurement teams, the message is simple: keeping up in the chip world

will soon require leveraging both quantum computing and AI together.

Quantum Computing and AI Integration in Semiconductor Innovation

Quantum computing works with qubits, which, unlike classical bits, can exist in superposition, representing both 0 and 1 simultaneously. This enables quantum processors to tackle complex simulations that classical computers struggle with, such as modelling atomic-level behaviour in new semiconductor materials.

AI enhances this capability. By applying predictive analytics to quantum simulations, machine learning models identify promising material candidates, predict their performance, and recommend adjustments. This transforms what was once a slow trial-and-error process into actionable insights, saving years of laboratory work.

Take Google’s Willow processor as an example. It is the follow-up to Sycamore, and while not built solely for materials research, it demonstrates how quantum systems can scale and reduce errors. When combined with machine learning, it provides an unprecedented view of material properties critical for chip innovation.

As Anima Anandkumar points out: “AI helps us turn the raw complexity of quantum simulations into insights engineers can actually use.”- Anima Anandkumar, Professor, Caltech & Senior Director of AI Research, Nvidia.

Together, AI and quantum computing are laying the foundation for a fundamentally new approach to chip design.

AI-Driven Material Science: Operational and Market Impact

When it comes to discovering new semiconductors, atomic-level precision is crucial. AI- powered quantum models can simulate electron behaviour in materials such as graphene, gallium nitride, or perovskites. This enables researchers to evaluate conductivity, energy efficiency, and durability before performing laboratory tests, greatly accelerating material qualification.

The practical impact is significant. Material validation traditionally took years, but early studies indicate that timelines can be shortened by 30 to 50 percent. This allows wafer fabs to operate more efficiently, align production with new innovations, and minimize idle time.

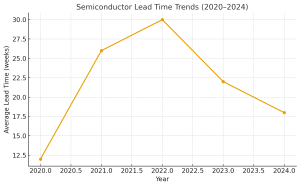

Market pressures further complicate the situation. During the 2021 shortage, lead times increased from approximately 12 weeks to over a year. With AI, companies can anticipate supply chain disruptions and proactively adjust sourcing strategies. Quantum simulations also expand the range of usable materials, reducing reliance on a single supplier or high-risk region.

Figure 1. Semiconductor lead times spiked from 12 weeks in 2020 to over 30 weeks in 2022 before easing. AI-quantum integration can help stabilize these fluctuations by enabling predictive analytics and diversified sourcing.

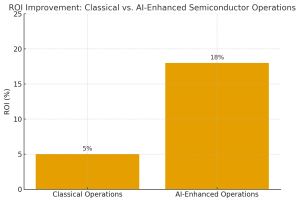

The return on investment is remarkable. According to Deloitte, companies that integrate AI into R&D and supply chain operations are achieving double-digit efficiency gains, primarily due to improved yield forecasting and reduced downtime. Google’s quantum research team has demonstrated that AI-driven simulations can narrow the list of promising materials from thousands to just a few within weeks, a process that would normally take years using classical computing. This dramatic compression of the R&D cycle fundamentally changes competitive dynamics.

Strategic Insights for Procurement and Supply Chain Leaders

For procurement and supply chain leaders, this is more than just a technical upgrade; it represents a genuine strategic advantage. AI-powered quantum tools help optimize lead times, enabling more precise supplier contracts and reducing the need for excess buffer stock. Predictive analytics also allow teams to identify potential risks before they affect wafer fabs or delay customer deliveries.

Supply chain resilience is also enhanced. When AI-guided quantum simulations confirm alternative semiconductors that can be sourced from different regions, procurement teams reduce exposure to geopolitical risks or natural disasters. This approach aligns with national initiatives such as the U.S. CHIPS and Science Act and the EU Chips Act, both of which promote stronger local production and more resilient sourcing strategies. Quantum-AI modelling provides the technical confidence required to qualify these alternative supply streams.

“The upward trajectory for the industry in the short-term is clear, but the companies that can manage their supply chains and attract and retain talent will be the ones well-positioned to sustain and benefit from the AI boom.”- Mark Gibson, Global Technology Leader, KPMG

Figure 2. Firms adopting AI-enhanced semiconductor operations achieve significantly higher ROI, with consulting studies reporting double-digit efficiency gains compared to classical operations.

At the end of the day, companies that successfully integrate these technologies do not just bring products to market faster; they also gain a genuine competitive edge in today’s unpredictable global markets. In the semiconductor industry, a delay of a few weeks can result in billions in lost revenue, so agility is essential for survival.

Future Outlook: Scaling Quantum AI Impact on Semiconductor Manufacturing

Looking ahead, the next major development appears to be full-stack quantum-AI design. Imagine quantum processors running full-chip simulations while AI optimizes them for speed, efficiency, and manufacturability. Although we are not there yet, incremental advances in photonic circuits and spintronic components are already producing tangible results.

For manufacturing teams, the challenge will be maintaining flexibility in supply chains. As new materials move from simulation to pilot production, procurement and fab teams must scale in coordination. Today’s quantum processors are not perfect, as they still face limitations in qubit counts, error rates, and scalability, but if progress continues, practical industrial applications could emerge within the next ten years. Companies that begin planning now, by developing roadmaps and forming strategic partnerships, will gain a significant advantage.

Conclusion

Right now, the semiconductor industry is at a critical turning point. Combining AI’s predictive capabilities with quantum computing’s atomic-level insights can accelerate discovery, shorten lead times, and make supply chains significantly more resilient. For engineers and procurement leaders, the message is clear: adopting AI-quantum integration is not just about technology; it is about remaining competitive. The next major advancement in silicon will not occur by chance. It will be carefully designed, optimized, and engineered using AI and quantum computing together.