Courtesy: RoHM

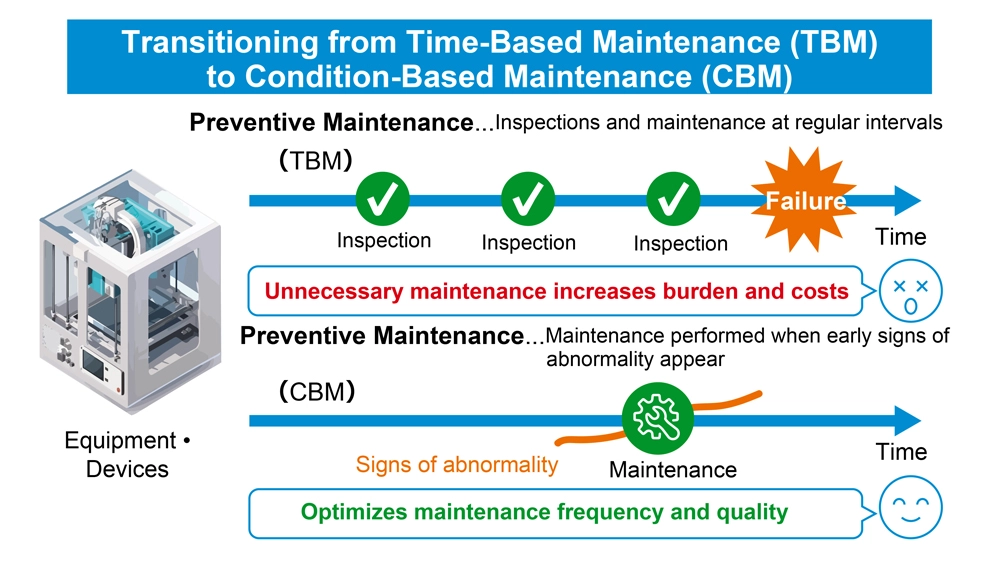

In the manufacturing industry, equipment maintenance has traditionally relied on preventive maintenance (TBM: Time-Based Maintenance), where inspections and part replacements are carried out at predetermined intervals. While effective to a degree, this approach often requires shutting down equipment that is still operating normally, resulting in unnecessary downtime, higher operating costs, and increased workload on production sites. In some cases, excessive inspection tasks can even introduce the problems they are intended to prevent—such as mistakes and human error.

Consequently, many manufacturers are now transitioning to predictive maintenance (CBM: Condition-Based Maintenance), which monitors equipment conditions in real time and performs maintenance only when early signs of abnormality are detected.

This white paper examines Solist-AI, ROHM’s AI-driven solution that enhances the efficiency and reliability of predictive maintenance.

- Transitioning from Time-Based Maintenance (TBM) to Condition-Based Maintenance (CBM)

The primary difference between preventive maintenance (TBM) and predictive maintenance (CBM) lies in how maintenance timing is determined. TBM schedules inspections and part replacements at fixed time intervals, independent of the equipment’s actual condition. In contrast, CBM performs maintenance only when truly necessary. AI plays a critical role in CBM by continuously monitoring parameters such as temperature, vibration, and current through sensors, processing large volumes of time-series data, and detecting early signs of abnormality from subtle pattern deviations.

By adopting predictive maintenance, manufacturers can avoid unnecessary shutdowns of equipment that is still operating normally. AI-driven optimisation of maintenance timing reduces operational costs and workload, while also preventing excessive inspections that may introduce procedural or human errors. Furthermore, because CBM ensures consistent maintenance quality without relying on technician intuition or experience, it is gaining attention as an effective solution to on-site challenges such as the shortage of skilled workers and persistent labour shortages.

- Shifting from Cloud-Based to Endpoint-Based Architecture

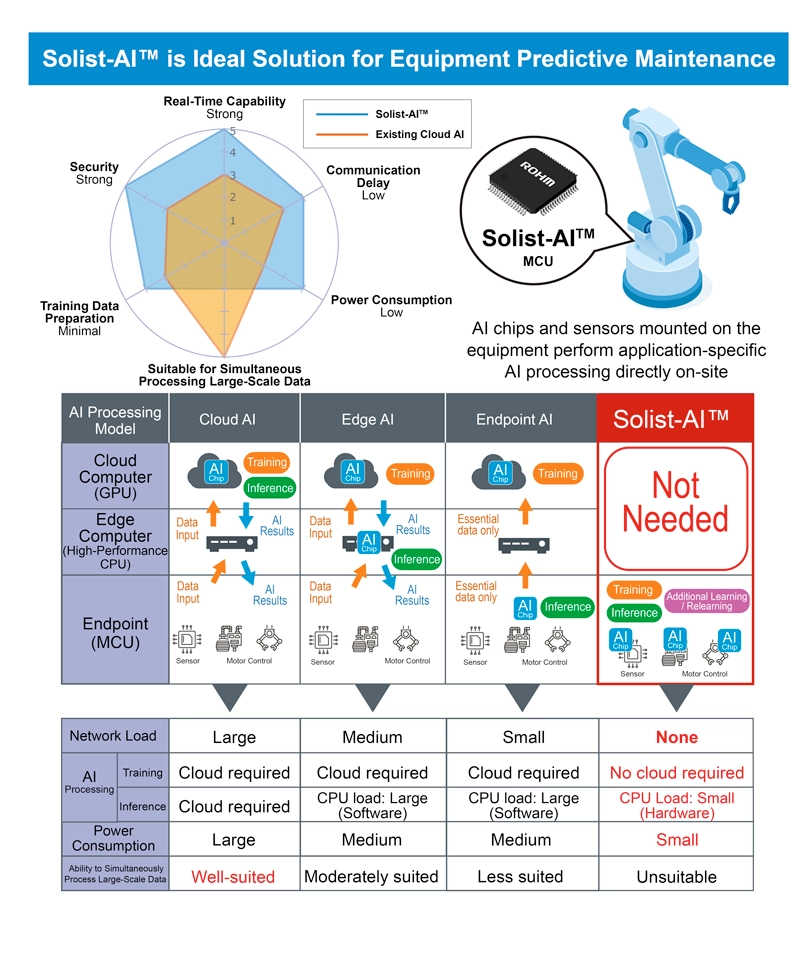

Conventional cloud-based AI systems face several challenges, including communication latency, the complexity of building and maintaining network infrastructure, and the added burden of implementing security measures to prevent data leaks during transmission.

These systems also require large volumes of training data to be collected and prepared in advance, making it difficult to account for variations in operating environments and equipment-specific differences at each site. High-precision AI processing also demands significant computational resources such as CPUs and GPUs, which inevitably increases power consumption.

This has led to the growing adoption of endpoint AI as a more practical alternative. By performing both learning and inference directly on devices equipped with sensors and MCUs, endpoint AI can adapt to the characteristics of individual machines, perform real-time processing, and maintain exceptionally low power consumption. In addition, because no data is transmitted to the cloud, it ensures a high level of security.

To support this paradigm, ROHM developed Solist-AI, an on-device AI solution optimised for edge computing, which is the core technology behind predictive maintenance. The name is derived from ‘Solution with On-device Learning IC for Standalone AI.’ Just like a ‘solist’ in music who performs independently, Solist-AI™ completes the entire AI workflow, from learning to inference, locally on the device without relying on the cloud or external networks.

While Solist-AI delivers significant advantages for on-device AI, it is not designed for large-scale data processing or image-based workloads compared to conventional AI architectures (cloud, edge, or endpoint types). For advanced analytics, such as detailed image diagnostics, cloud-based AI remains the preferred solution.

For applications that do not require advanced analysis, Solist-AI offers a major benefit: substantial cost savings by eliminating expenses associated with network infrastructure and cloud service fees.

And with ongoing learning capabilities, Solist-AI can continuously update its understanding of equipment deterioration over time. This greatly improves responsiveness to both normal and abnormal conditions as machines age, making it a compelling alternative to traditional AI solutions.

- Solist-AI: The Optimal Solution for Predictive Maintenance

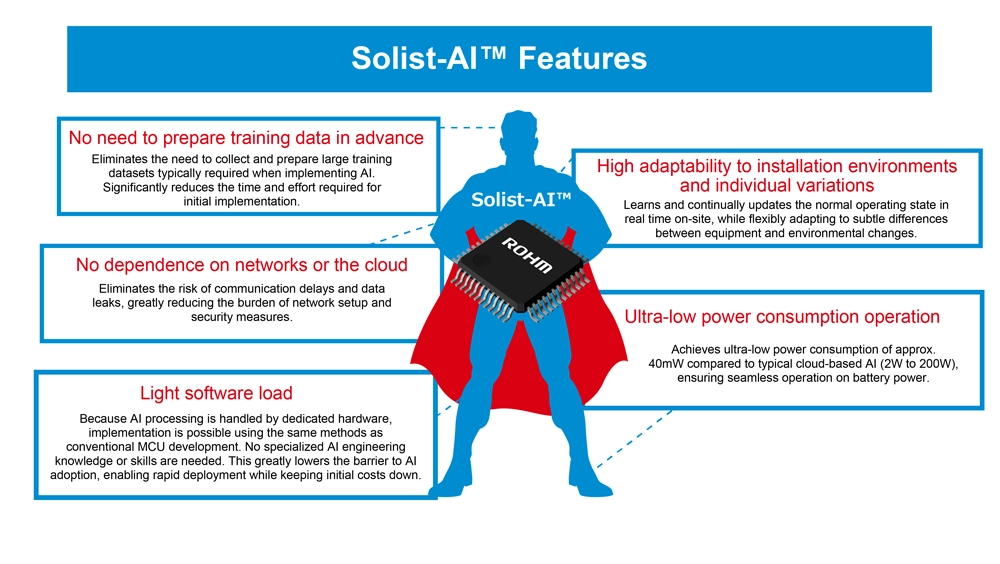

Unlike general-purpose AI processors, Solist-AI is purpose-built for targeted use cases such as failure prediction and anomaly detection. The ability to train and fine-tune models directly on-site based on the actual operating environment ensures flexible adaptation to equipment variations and changing ambient conditions.

At the heart of the solution is the Solist-AI MCU, which integrates ROHM’s proprietary AI accelerator AxlCORE-ODL (On-Device Learning). This accelerator performs a three-layer neural network and FFT (Fast Fourier Transform) processing in dedicated hardware, enabling real-time detection and notification of various anomalies and operational changes in the field.

The biggest advantage of Solist-AI lies in its simplicity as a standalone AI system, requiring only a sensor and MCU. Whereas conventional AI solutions depend on cloud access or network connectivity, Solist-AI operates completely independent of any network infrastructure. This allows it to be easily retrofitted into existing equipment while eliminating concerns related to communication delays and data leakage.

Equipped with a built-in AI accelerator, AxlCORE-ODL learns and infers data from sensors–such as vibration, temperature, and current—— in real time. By quantifying subtle deviations from normal patterns, it identifies and alerts users to early signs of abnormality.

Operating at an exceptionally low power level of approximately 40 mW, Solist-AI stands in stark contrast to conventional cloud-based AI systems that typically consume anywhere from 2W to 200W. This makes it well-suited for battery-powered devices and ideal for retrofitting into existing equipment. As a result, it enhances maintenance and operational efficiency across a wide range of industrial assets, including robots, motors, and cooling fans.

In addition, a variety of support tools are available, including Solist-AI Sim, which enables preliminary verification of AI suitability, and Solist-AI Scope, which offers real-time visualisation of AI behaviour. These tools enable implementation and evaluation without requiring specialised AI expertise, greatly lowering the barrier to adoption.

Example of Integration with AE (Acoustic Emission) Sensors

Combining AE sensors and Solist-AI enables high precision detection of abnormalities that are extremely difficult to identify manually, such as insufficient bearing lubrication or microscopic surface damage. The system analyses multiple AE sensor outputs (including peak amplitude, average value, energy, and event count) across multiple dimensions. The AI numerically quantifies the degree of abnormality, allowing early detection of emerging issues and supporting timely, condition-based maintenance. Because the progression of anomaly levels can be visually understood without requiring specialised expertise, this solution is widely regarded for its suitability in real-world on-site operation.

- Summary

ROHM’s Solist-AI is a true endpoint solution that functions independently of the cloud, delivering a practical approach to predictive maintenance. By completing both learning and inference in real-time using only a sensor and MCU, it eliminates the need for network connectivity, consumes very low power, and offers robust security for safe, reliable operation. Dedicated support tools allow even personnel without AI expertise to easily deploy and evaluate the system.

A wide range of proven application examples, including detecting abnormal fan motor vibrations and identifying changes in current waveforms, demonstrate how Solist-AI substantially lowers the barriers to implementation.

Going forward, ROHM is expanding the product lineup and developing higher-performance models to support broader use across maintenance and other applications. Solist-AI brings new value to manufacturing sites by quickly detecting ‘deviations from normal’ on the factory floor and autonomously prompting appropriate actions

To help engineers learn more about and fully leverage Solist-AI, ROHM invites users to connect through a dedicated community, ‘Solist-AI Open Lab: Getting Started’ on its technical platform, Engineer Social Hub (available in Japanese; registration/login required). In addition to accessing detailed information on Solist-AI, members can ask questions, share feedback, and discuss evaluation and implementation challenges, so we encourage you to participate.