As one of the core team partners within the European pilot line project PI-SCALE Fraunhofer FEP presents first demonstrators of flexible OLED out from this project. The demonstrators represent results from first pilot line production within the PI-SCALE project at the IDW 23rd International Display Workshops in Fukuoka, Japan, from December 7– 9, 2016 on 4th floor, booth no. 13. Thousands of high tech SMEs in Europe often lack access to advanced, cost-intensive infrastructures and expertise needed to manufacture new and innovative products. The European Pilot Line Initiative PI-SCALE is focusing on especially this gap – to help companies take photonic technologies from lab into market by creating a world-leading open access pilot line in Europe for the manufacturing and system-level integration of flexible OLEDs.

Flexible OLED lighting applications are supposed to open up a wide range of new possibilities for special lighting applications e.g. in medical applications for light therapy, in architecture, aircraft and railway as a lightweight opportunity, for various touch-display applications in automotive industry. Ideas for such applications and a lot of OLED products are already existing. Also, the latest research results and technological know-how is ready to be used.

In 2016 the PI-SCALE project started with the ambition to create a world-leading open access pilot line, based in Europe, for companies interested in the manufacture and system-level integration of flexible OLEDs into products. This will be achieved by bringing together the very best of the existing European infrastructure and know-how on flexible OLEDs from different locations into one pilot line. The pilot line service will enable companies of all sizes to quickly and cost effectively test and scale up their flexible OLED lighting or signage concepts and bring them to a level where they are ready to be transferred to a mass production facility.

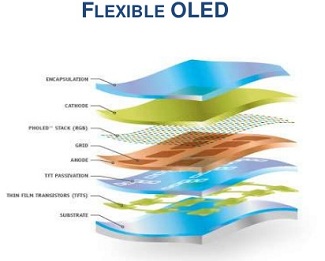

Fraunhofer FEP is responsible for the R2R anode deposition on barrier web, which is produced by the project partner Holst Centre as well as for the OLED-deposition by using evaporation processes. The OLED-deposition at Fraunhofer FEP can be done in Roll-to-Roll (R2R) and Sheet-to-Sheet (S2S) processes. In R2R it is possible to produce endless long stripes with up to 30 lm/W and in S2S high quality OLEDs with a high performance can be produced. As substrates the pilot line mainly uses plastic web and ultra-thin-glass.

Project leader Claudia Keibler from Fraunhofer FEP is pleased: ”We could demonstrate that the S2S and R2R process flows of the pilot line are working by producing up to 15 m long OLED-stripes with an efficiency higher than 30 lm/W and with nearly 100% yield.” In total, around 50 m of OLED were deposited in the R2R process within the PI-SCALE project. They have an average efficiency of 30 lm/W. To show the reliability and reproducibility of the pilot line it is planned to produce 15 m long OLEDs in R2R monthly and to evaluate them. In S2S a monthly monitor batch of four 6inch plates will be done, to demonstrate the operational capability of the pilot line production processes.

In order to achieve this and to proof the functionality of the pilot line service, partners all along the whole value chain are represented in PI-SCALE – from material supplier up to the end user. Together with the other technology partners of the pilot line customer specific OLED solutions are offered considering also the price-performance ratio. From July 2017 the pilot line service will be ready to supply customers with unique customized flexible OLEDs on thin-glass as well as on plastic foil, which can be produced in R2R and S2S.