Manufacturing today depends on processes that balance speed, precision, and scalability. Among them, injection molding has become indispensable for industries ranging from healthcare to consumer goods. Its ability to deliver identical, high-quality parts in massive volumes makes it one of the most reliable and cost-effective production methods. But what makes this process so vital, and how exactly does it work?

Understanding Injection Molding

Fundamentally, injection molding is about thrusting molten material into a precisely crafted mold, where it solidifies and takes on its final shape. Plastics are the stalwart of the operation, but producers also apply it to metals and testing uses in new industries. The greatest strength of injection molding is consistency and efficiency once a mold has been made, it can be used to churn out hundreds of thousands of duplicate parts with little deviation.

Unlike subtractive methods such as CNC machining, injection molding is less wasteful of material and can be more flexible in terms of design, with the ability to create everything from small medical devices to large automotive panels.

Industries that Depend on Injection Molding

- Food and Beverage

From yogurt cups to condiment containers, the packaging business relies heavily on injection molding for its light, disposable products. Moving beyond packaging, researchers at one of the University are testing whether this process can be used to mass-produce plant-based meat substitutes, demonstrating how versatile the method can be. In contrast to 3D printing, injection molding offers cost savings and is able to maintain taste and texture in food applications.

- Healthcare and Medical Devices

The medical sector applies injection molding in the production of syringes, implants, and wearables. Due to the stringent regulatory conditions, manufacturers tend to include sensors within the mold to check for temperature and pressure, allowing for perfect outcomes. Robotic equipment is also utilized, which removes faulty components automatically to ensure high levels of safety in patient-care products.

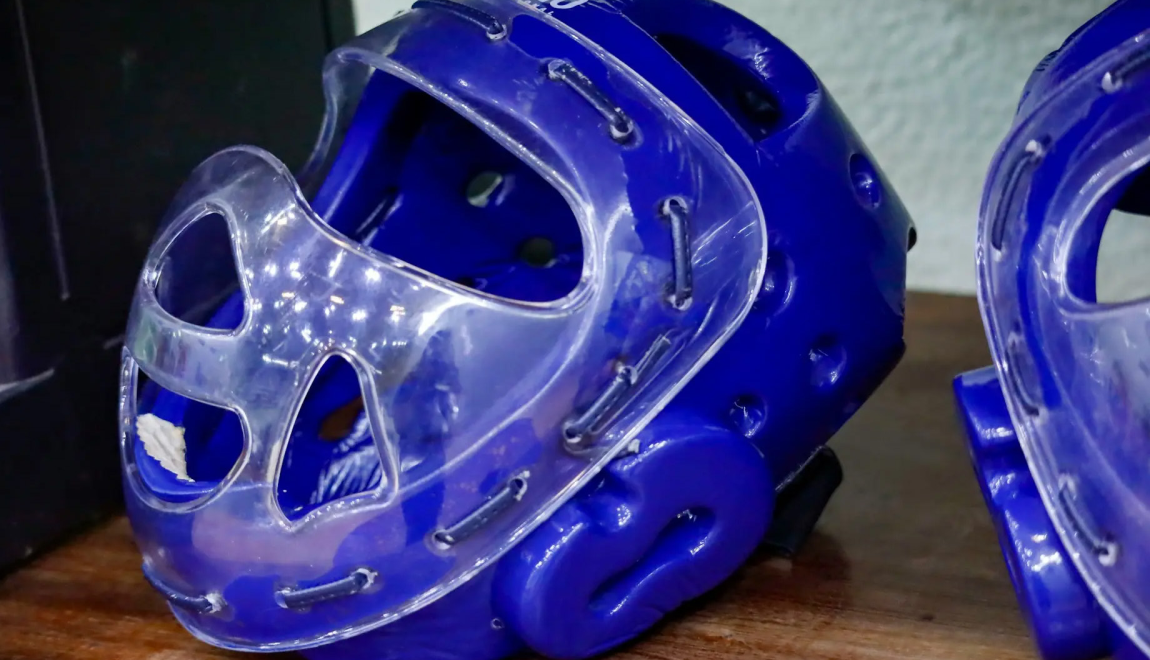

- Sporting Goods and Consumer Products

Leisure goods used daily picnic tableware, coolers, and even high-precision golf clubs are produced with this process as well. Metal injection molding enables golf club manufacturers to create products that improve performance and feedback. Molding single-piece coolers thinner but stronger walls speaks to the process’s efficiency and resilience.

The Injection Molding Process

In any industry and whether small, medium, or large, the injection molding process adheres to a systematic approach:

- Material Selection – Companies select metals or polymers according to strength, flexibility, durability, or resistance characteristics. Polypropylene is suitable for packaging food, while polycarbonate resists UV exposure for use outside.

- Design of Mold – Designers make precise steel or aluminum molds with orientation, core, cavity, and mold base in mind. CNC machining is usually employed to cut the mold exactly.

- Clamping – A clamping mechanism provides pressure to keep the mold halves tightly closed, preventing any leak during the process of injection.

- Injection – Pellets are melted into molten form, blended by a reciprocating screw, and injected into the mold at regulated velocities and pressures.

- Dwelling – Pressure is held for a temporary period to guarantee the molten material fills all the cavities of the mold.

- Cooling – The part solidifies within the mold, a phase often constituting the bulk of cycle time.

- Opening and Removal – After cooling, the mold is opened and ejector pins force the part out. Any remaining flash material is removed and sometimes recycled.

- Inspection – Finished parts are visually inspected and tested to detect defects, maintaining consistent quality control.

Why Injection Molding Remains Essential

The scalability, accuracy, and versatility to perform in various industries of the process make injection molding a corner stone of contemporary manufacturing. From life-saving medical technologies to common consumer products, the process continues to transform with automation, robotics, and intelligent sensors, which guarantee ever-greater levels of quality and efficiency.

As industries seek faster, more sustainable, and more innovative ways to produce goods, injection molding remains a cornerstone technology that bridges traditional manufacturing with future possibilities.

(This article has been adapted and modified from content on Revolutionized.)