LED soldering is the process of joining electronic components of light-emitting diodes (LEDs) to a printed circuit board (PCB) or other substrates using a soldering material, typically a tin-lead alloy or lead-free solder. The process ensures proper electrical and mechanical connections between the LED terminals and the PCB.

How LED Soldering Works

- Preparation:

- Ensure that the PCB and LED components are clean and free from debris or oxidation.

- Apply solder paste to the PCB pads where the LED will be placed.

- Placement:

- Position the LED on the solder-pasted area using precision tools like tweezers or pick-and-place machines.

- Soldering Process:

- Hand Soldering:

- Use a soldering iron to heat the LED terminals and solder pads.

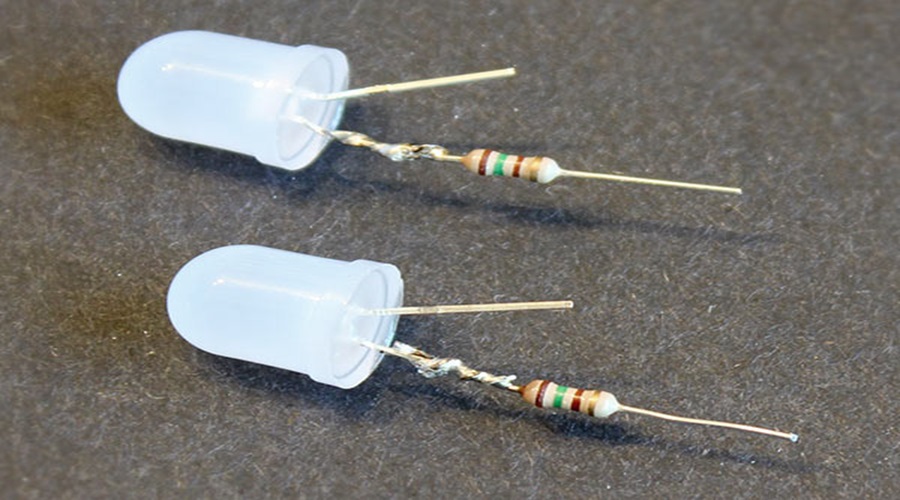

- Apply solder wire to create a strong electrical connection.

- Reflow Soldering (for mass production):

- The PCB with the LED is placed in a reflow oven, where heat melts the solder paste, creating a secure connection.

- Wave Soldering:

- For through-hole LEDs, the PCB is passed over a molten solder wave to attach the components.

- Hand Soldering:

- Inspection:

- Verify the connections using visual inspection, automated optical inspection (AOI), or X-ray inspection.

- Testing:

- Test the soldered LED for functionality, ensuring it emits light and operates as intended.

LED Soldering Process

- Manual Soldering:

- Used for prototypes or small batches.

- Involves a soldering iron and manual placement.

- Automated Soldering:

- Uses pick-and-place machines and reflow ovens for large-scale production.

- Soldering Techniques:

- Surface-Mount Technology (SMT): Common for LEDs mounted on flat PCBs.

- Through-Hole Technology (THT): Used for LEDs requiring a stronger mechanical bond.

- Cooling:

- Allow the soldered assembly to cool, solidifying the solder joints.

Uses & Applications of LED Soldering

- Consumer Electronics:

- LED displays, backlights, and indicators in devices.

- Automotive:

- Headlights, tail lights, and dashboard indicators.

- Industrial:

- Machine vision lighting and control panels.

- Residential and Commercial Lighting:

- LED bulbs, tube lights, and architectural lighting.

- Signage and Displays:

- Advertising boards, billboards, and traffic signals.

Advantages of LED Soldering

- Durability:

- Provides a robust mechanical and electrical connection.

- Scalability:

- Suitable for mass production using automated techniques.

- Efficiency:

- Reflow soldering ensures uniform heat distribution and reliable connections.

- Versatility:

- Applicable to various LED sizes and designs.

- Energy Efficiency:

- LED soldering supports energy-efficient lighting technologies.

Disadvantages of LED Soldering

- Heat Sensitivity:

- LEDs are sensitive to high temperatures, which can damage components if not controlled.

- Complexity:

- Requires precision in placement and temperature control during soldering.

- Material Costs:

- Lead-free solders and automated equipment can increase production costs.

- Risk of Cold Solder Joints:

- Improper soldering can result in weak or intermittent connections.

- Environmental Concerns:

- Lead-based solder can pose environmental and health risks if not disposed of properly.