Future-proof quality assurance for power electronics through sintering paste inspection with multi-line SPI

Higher operating temperatures, thinner interconnection layers, 10 times the longevity – the advantages of sintering pastes over solder pastes have long been recognized in the field of power electronics. Not least for this reason, sintering pastes are preferred in system-critical technologies such as “green energy” and e-mobility. Here, for example, IGBTs have become the central component in converters for all types of electric drives: wind turbines, solar power generation, battery charging – hardly any future technology would be conceivable without the “all-rounder” sintering paste. However, sintering is more prone to errors than soldering paste printing. Furthermore, defects are more difficult to detect and rectify – critical failures in the field are the result. To avoid this, GÖPEL electronic has now added an inspection system specifically for sintering paste to its Multi Line platform.

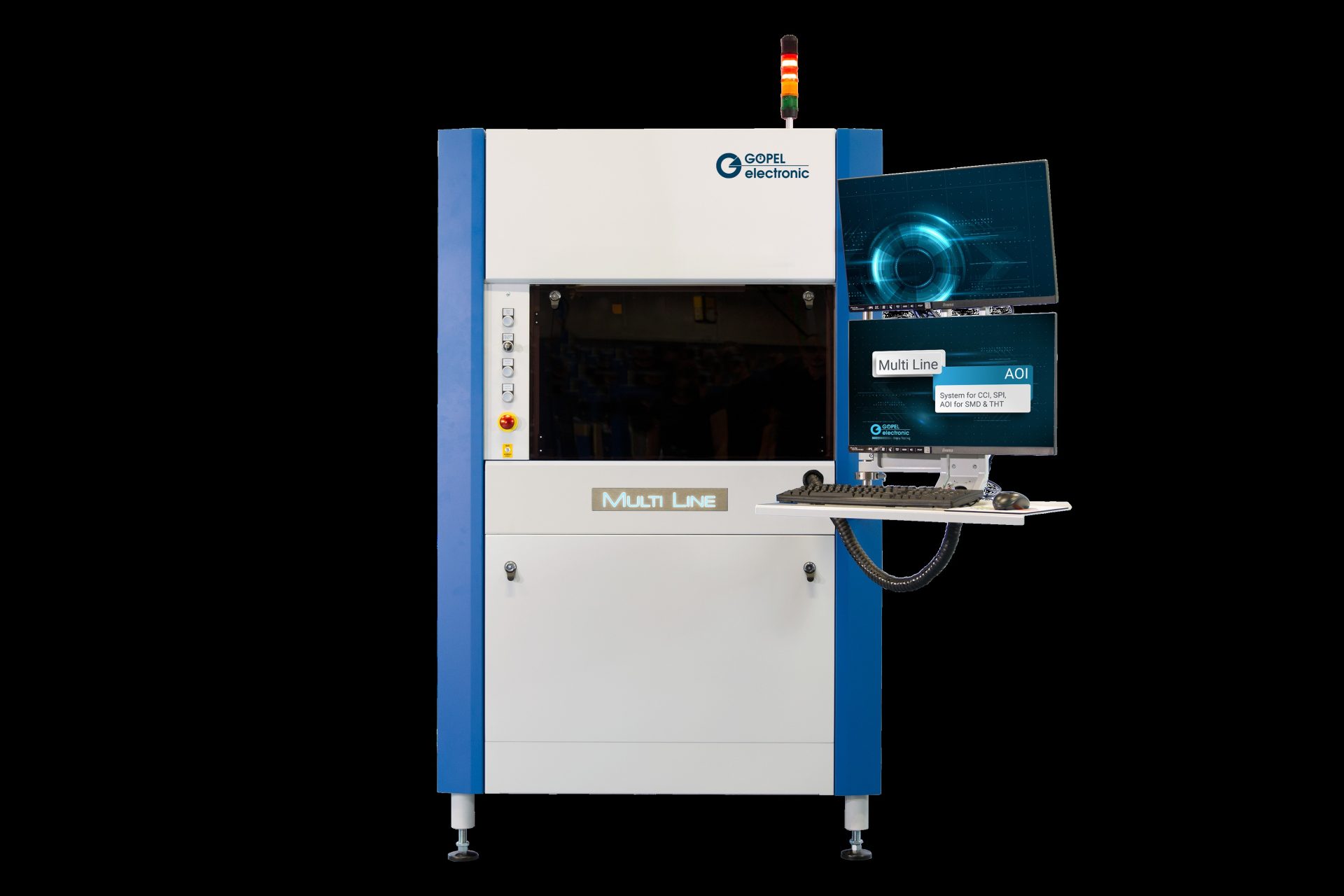

The Multi Line SPI is a cost-effective 3D inline system for automated inspection of sintering paste. Based on the Multi Line platform, it is a customized solution for small and medium-sized companies with high quality standards; it can also be used for solder pastes. The telecentric 3D camera module is used to inspect solder and sinter paste without shadows for shape, area, coplanarity, height, bridges, volume and X/Y offset. Equipped with two digital fringe projectors for shadow-free 3D image capturing, it has a resolution of 15µm/pixel, a height measurement accuracy of 1µm and a height resolution of 0.2 µm. This means that measurement values can be obtained precisely and repeatedly.

Generation of an inspection program for sinter paste inspection takes only a few minutes: CAD data or a reference layout is sufficient. Users who already use GÖPEL electronic software for programming SMD, THT or CCI systems can learn the additional sinter paste functions with little training. In addition, the data import, verification and statistics software are identical to the other inspection systems from GÖPEL electronic. This is where the platform concept of the Multi Line series really pays off: the uniform, powerful operating and evaluation software across all devices reduces training and programming effort, enabling flexible and optimized staff deployment planning.