The global automotive industry is undergoing a fundamental transformation moving from internal combustion engines (ICEs) to electric and hybrid vehicles that redefine mobility as sustainable, intelligent, and efficient.

This shift is not merely regulatory-driven; it’s fueled by a shared pursuit of carbon neutrality, cost-effectiveness, and consumer demand for cleaner mobility options.

Hybrid electric technology has proven to be the most practical bridge to date between traditional combustion and complete electrification. Providing the versatility of twin propulsion — electric motor and ICE — hybrid powertrains give the advantages of fuel economy, lower emissions, and a smoother transition for both consumers and manufacturers.

From regenerative braking to capture kinetic energy to AI-enabled energy management optimizing power delivery, hybrids are the sophisticated union of software and engineering. As countries pledge net-zero, and OEMs retool product strategies, hybrid technology is not merely a transition measure — it’s the strategic foundation of the auto decarbonization agenda.

Innovations Driving Hybrid Systems

- Solid-State & Next-Gen Lithium-Ion Batteries

Next-generation solid-state batteries hold the potential for greater energy density, quicker charging, and increased safety. Their ability to double the energy storage capacity and halve the charging time makes it a game-changer for hybrid and plug-in hybrid vehicles.

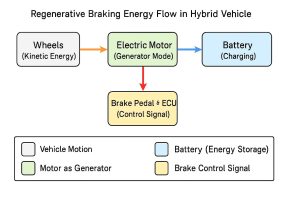

- Regenerative Braking & E-Axle Integration

Regenerative braking captures kinetic energy and converts it into electricity during braking, pumping it back into the battery. Coupled with e-axle technology, this integration optimizes drivetrain efficiency and performance.

- Lightweight Composites for Higher Efficiency

Advances in carbon-fiber-reinforced plastics and aluminum alloys allow automakers to shave weight, increase efficiency, and enhance range — all without sacrificing safety.

- AI-Powered Energy Management Systems

Artificial intelligence is now at the heart of hybrid optimization — learning driving habits, anticipating power needs, and controlling energy transfer between engine, motor, and battery for optimum efficiency.

Industry Insights: Mercedes-Benz on Hybrid Innovation

Rahul Kumar Shah, Senior Engineer at Mercedes-Benz Research & Development, outlines the engineering philosophy behind the company’s next-gen hybrid powertrains.

“At Mercedes-Benz, we view hybridisation not as an interim solution, but as a masterclass in energy orchestration. Our focus is on creating a seamless dialogue between the combustion engine and electric motor — ensuring the right power source is deployed at the right time to deliver maximum efficiency and a signature Mercedes driving experience.”

Optimizing Hybrid Powertrain Architectures:

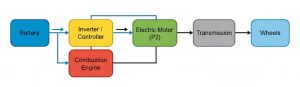

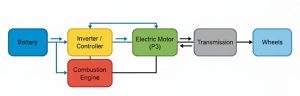

“We have advanced from conventional parallel systems to sophisticated P2 and P3 architectures. By placing high-torque electric motors strategically within the drivetrain, we eliminate turbo lag and allow smaller, thermally efficient combustion engines to deliver spirited performance. Combined with predictive AI energy management, our vehicles decide in real time whether to operate in electric mode, recharge, or blend both power sources for optimal efficiency.”

Figure (1)

Figure (2)

The P2 Hybrid (first diagram) places the electric motor between the engine and transmission, allowing it to drive the wheels directly alongside the engine or independently. The P3 Hybrid (second diagram) places the electric motor on the transmission output shaft, leveraging greater torque multiplication but coupling the electric drive to the transmission output shaft. Both are Parallel PHEVs using a battery and inverter to manage power flow to the wheels.

Regenerative Braking:

“Our eDrive motors can decelerate the car up to 3 m/s² using purely regenerative energy. Coupled with our ESP HEV system, regenerative and mechanical braking are blended seamlessly to ensure vehicle stability and natural pedal feel. Integration with navigation and radar allows the vehicle to preemptively harvest energy — effectively ‘sailing on electricity.”

During regenerative braking, the wheels’ kinetic energy is converted by the motor (in generator mode) into electrical energy, which charges the battery. This process is triggered by a control signal from the brake pedal and ECU.

Thermal Management:

“Managing heat across the combustion engine, electric motor, and battery is essential. We maintain optimal battery temperatures between 20–40°C and reuse waste heat for cabin and coolant heating, reducing overall energy draw and improving efficiency.”

Solid-State Batteries:

“For hybrids, the real advantage lies in power density and durability. Solid-state cells can deliver and absorb charge much faster, enabling more efficient regenerative braking and smoother electric boosts. They are set to become the ultra-durable heart of next-generation hybrid powertrains.”

The Future of Hybrid Powertrains

The hybrid era is entering a smarter, cleaner, and more connected phase. Over the next decade, hybrid systems will evolve from being a bridge technology to a core pillar of sustainable mobility.

- Plug-in Hybrids Take Center Stage

Plug-in hybrids (PHEVs) will lead the transition, providing longer electric-only ranges and rapid charging. With bi-directional charging (V2G), they’ll also supply homes or return energy to the grid, making vehicles portable energy centers.

- Hydrogen Enters the Hybrid Mix

Hybrid powertrains assisted by hydrogen will appear, particularly in commercial and long-distance vehicles. Blending fuel cell stacks with electric drives, they will provide zero-emission mobility with rapid refueling and long range.

- Modular Electric Platforms

At-scale automakers are shifting to scalable modular architectures that integrate the battery, e-axle, and drive unit into flexible “skateboard” configurations. These platforms will reduce their costs and enable software-defined performance updates through over-the-air upgrades.

- AI-Optimized Energy Management

Artificial intelligence will power real-time power delivery, anticipating traffic and terrain to balance efficiency with performance. Future hybrids will be able to learn, adjust, and self-optimize, combining intelligence with propulsion.

- Smart Materials & Circular Manufacturing

The hybrids of tomorrow will be lighter and cleaner — constructed from recycled composites, graphene-reinforced metals, and bio-based plastics. Closed-loop recycling will enable hybrid production to become more sustainable from start to finish.

Conclusion

Hybrid powertrains are no longer a bridge they’re becoming the cornerstone of an intelligent, networked mobility ecosystem.

As electrification grows and carbon-neutral goals firm up, hybrids will become smarter, self-tuning systems that efficiently couple combustion with electric precision.

Next-generation hybrid platforms will talk to smart grids, learn from the behavior of drivers, and self-regulate energy across varying propulsion sources from batteries to hydrogen cells. Optimization using AI, predictive maintenance, and cloud-based analytics will transform vehicles into operating modes, charging, and interacting with their surroundings.

Hybrids aren’t just a bridge—they’re the bold intersection where combustion and electrification unite to rewrite the future.