By combining two distinct approaches into an integrated workflow, Singapore University of Technology and Design (SUTD) researchers have developed a novel automated process for designing and fabricating customized soft robots. Their method can be applied to other kinds of soft robots—allowing their mechanical properties to be tailored in an accessible manner.

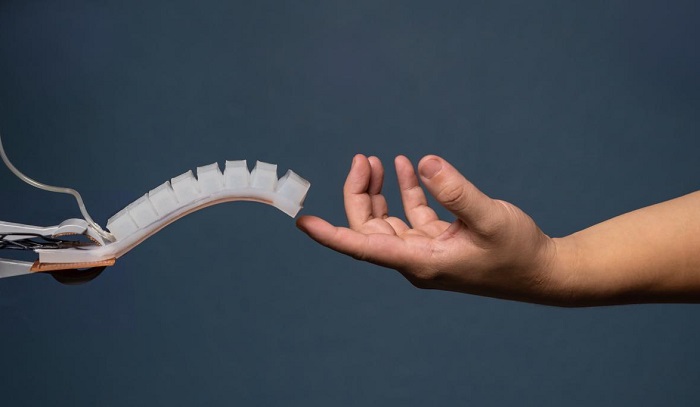

Though robots are often depicted as stiff, metallic structures, an emerging class of pliable machines known as soft robots is rapidly gaining traction. Inspired by the flexible forms of living organisms, soft robots have wide applications in sensing, movement, object grasping and manipulation, among others. Yet, such robots are still mostly fabricated through manual casting techniques—limiting the complexity and geometries that can be achieved.

“Most fabrication approaches are predominantly manual due to a lack of standard tools,” said SUTD Assistant Professor, who led the study. “But 3D printing or additive manufacturing is slowly coming into play as it facilitates repeatability and allows more complex designs—improving quality and performance.”

According to a researcher, embedded 3D printing—wherein various material inks are extruded in a supportive matrix—is especially suited for fabricating soft robots made of multiple materials or composites. However, to ensure that these robots are optimally designed, the team turned to topology optimisation (TO), where mathematical models are employed to design bespoke structures within a set of constraints.

By automating these two key steps in a single framework, the researchers hoped to develop an integrated workflow for creating customized soft robots and minimize potential errors along the way. For the study, the group used a swimming autonomous robot inspired by batoids. The workflow starts by defining the robot’s fin geometry, after which TO is used to generate the desired structure with desired properties within prescribed material and motion constraints. The optimized design is then transformed into a code that is read by the team’s custom-built 3D printers, which in turn fabricate the robot.

The batoid-inspired soft robots were designed to survive the marine environment’s harsh conditions and the approach focused on tailoring their fin composition and assessing how these changes could impact the fabricated robot’s swimming performance.

Specifically, three types of fins were created—with two fins respectively made of soft and stiff materials as well as a third fin designed through TO combining the two materials. Unlike the first two fins, which were fabricated using traditional methods, the third composite fin was made following the integrated workflow.

Incredibly, the soft robot with the optimized composite fins was 50 percent faster than its counterpart with the traditionally casted soft fin, with a speed slightly higher than the robot with the hard fin. The same prototype with the composite fin also turned roughly 30 percent faster compared to the soft fin and had the smallest turning radius among the three robots—making it better at maneuvering through water.

Having successfully demonstrated the effectiveness of their approach, Researcher noted that their workflow for fabricating optimized, multi-material soft robots can be universally applied to design other soft robots.

“For example, if we’re building a sensor, our objective in TO could be to tailor the electrical conductivity of certain portions of the structure,” Researcher said. “Customizing optical, thermal, electrical, as well as other physico-chemical properties would also be interesting for other applications.”