As emerging glasses and systems bring the virtual and physical worlds closer together than ever before, making navigation, entertainment, and even gaming way easier and more exciting, it is the power of electronics that makes it happen. In such a scenario, let’s examine the technology that makes it possible, seamless, and modern. As we move into the topic, it’s essential to emphasize that the PCB is the most crucial central platform that connects and organizes all the electronic components in a smart glass or an AR/VR device.

What type of PCB is used in Smart Glasses?

Due to the need for flexibility, adaptability, and reliability, the majority of smart glasses today are manufactured using Flexible Printed Circuit Boards (FPCBs). These are thin, lightweight circuit boards made from pliable materials that bend easily without breaking. As opposed to the rigid circuit boards, FPCBs are made with the intent to empower technology with convenience.

What makes FPCBs the go-to Choice?

PCBs enable engineers to redefine electronics with unique shapes. As it can withstand repeated bending cycles, by default, it becomes an ideal choice for compact and curved designs of smart glasses or AR/VR gear. It is a prime example of how technology integrated with aesthetics and need can empower a whole segment of innovation and seamlessness.

Smart Glasses and FPCBs are a match made in heaven, as FPCBs not only constitute the central platform, which is what a PCB usually does, but also enable the engineers to render various specific characteristics of glasses into the segment of Smart Glasses.

Electrical yet Appealing & Convenient: Secrets

To make a device fitted with so many components, yet maintain it for optimal use as a glass, necessitates a plethora of considerations to be ticked. This takes us to the next part of our story, which is the types of FPCBs depending on the materials it is made of. These materials render significant properties to the FPCBs, enabling them to not only facilitate technology but also combat its ills.

Primary materials used in these applications are:

- Polyimide (PI): The most commonly used substrate for flexible PCBs, polyimide offers outstanding thermal stability (up to 400 °C) and high mechanical strength. It can withstand thousands of bending cycles, making it ideal for the constantly moving and compact environment of smart eyewear.

- Polyester (PET): A more economical alternative to polyimide, PET provides decent flexibility but is less durable. It works best in static or low-bend applications, and is often chosen for simpler or less demanding wearable designs.

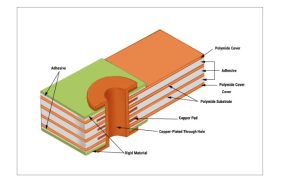

- Copper Foil: Copper is the standard conductor in flexible PCBs. Among the types, rolled-annealed (RA) copper is preferred over electrodeposited (ED) copper because of its superior flexibility and fatigue resistance—key for handling repeated bends in devices like smart glasses.

- Adhesives and Coverlays: Adhesives secure the layers of a flexible PCB, while coverlays (thin protective films) safeguard the circuitry. Both must retain flexibility and adhesion under stress to prevent issues like delamination during everyday use.

Engineers frequently favor polyimide-based substrates for their durability, particularly in premium AR glasses where long-term reliability is essential. Beyond strength, the choice of material also influences signal performance—polyimide’s low dielectric loss makes it well-suited for high-frequency applications such as 5G connectivity in smart devices.

Design Considerations with FPCBs

Since smart glasses can be subjected to repeated bending and need proper signals to enable their proper usage, it is important to design them accordingly to suit future needs. In engineering terms following considerations rank the highest:

Bending Radius:

- Maintain ≥10× PCB thickness for dynamic bends, ≥3× for static.

- Example: 0.1 mm PCB → 1 mm minimum dynamic bend radius.

Trace Layout & Spacing:

- Route traces perpendicular to bend lines.

- Avoid vias/components in bend zones.

- Keep ≥0.1 mm spacing to prevent shorts during flexing.

Tear-Drop Pads:

- Use tear-drop geometry at trace–pad junctions to minimize stress concentration and cracking.

Layer Stack-Up:

- Use symmetrical stack-ups to keep the neutral axis centered.

- Reduces stress on multilayer FPCs, especially in curved frame designs.

In AR glasses, an FPC can route signals from the microdisplay in the lens to the control unit in the frame, flexing around corners without adding bulk. This ability to combine compact routing with mechanical flexibility makes FPCs fundamental to wearable design.

Is it all Always Good with FPCBs?

To give a straight answer, no. Neither is the case with any technology in the world. Let’s look into certain challenges that FPCBs have to offer when it comes to Smart Glasses:

- Maintaining Signal Integrity: With FPCBs having thin dielectric layers, high-frequency signals for wireless connectivity can face significant challenges. To counter this, manufacturers often turn towards low-loss materials like modified polyimide and ensure precise impedance control, targeting values like 50 ohms for optimal performance.

- Ensuring Bend Durability: Repeated flexing can fatigue copper traces. Mitigation strategies include using rolled-annealed (RA) copper and reinforcing bend zones with stiffeners or extra coverlay layers to better distribute mechanical stress.

- Miniaturization: Smart eyewear requires ultra-compact PCBs with high-density interconnects. Techniques like laser-drilled microvias (as small as 0.05 mm) enable dense, high-performance circuit layouts.

By leveraging these methods, manufacturers can deliver flexible PCBs that meet the strict demands of smart eyewear—combining durability, miniaturization, and high-speed signal integrity where Flexible PCBs are central to smart eyewear, enabling sleek, lightweight designs. Success depends on material choice, proper bend-radius design, and precise rigid-flex assembly—key factors for building reliable, innovative wearables