In the budget for 2021, the Indian government sanctioned Rs. 76,000 crores for the India Semiconductor Mission (ISM). Today, after nearly five years, there is a need for an additional investment of Rs. 10,000-15,000 crores in the next two to three years to boost domestic PCB manufacturing to reduce import dependency below 50%, according to JS Gujral, MD, Syrma SGS.

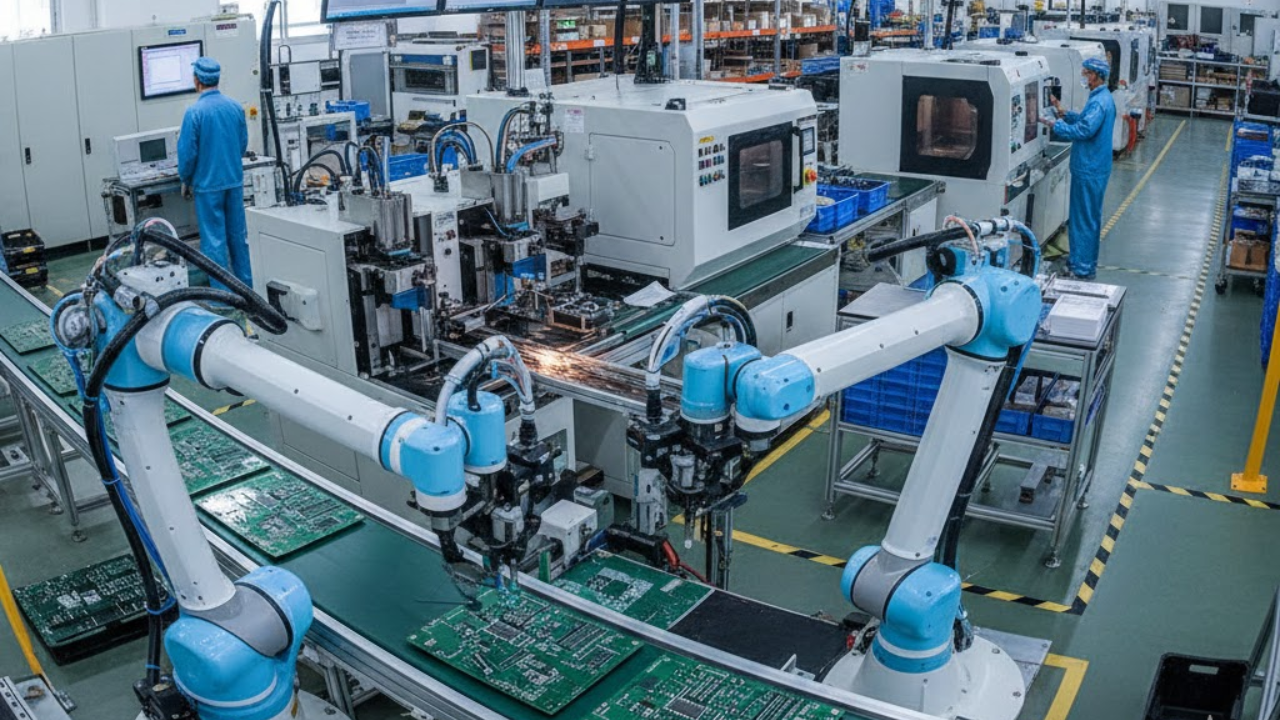

Currently, India demands PCBs worth nearly Rs. 50,000 crores, and only 10% of that demand is met locally, while the rest is fulfilled through imports from China, Taiwan and other nations. The aim is to increase the production to a worth of Rs. 20,000 in the next three years when the demand itself will rise to Rs. 70,000 worth.

From the many factors holding India back, the raw material bottle neck is a significant problem. Raw materials make up for nearly 60% of the total cost of the PCB. Copper Clad Laminate (CCL) is one of the primary materials used in PCB manufacturing. It covers nearly 27% of that raw material cost. While India is gradually progressing towards its complete domestic manufacturing, there are other burdens such as the copper foil, pre pregs, and specialized chemicals. These three are largely imported which add to the exorbitant costs of PCBs manufactured in India, making them costly and less competitive in the global market.

Experts recommend the increase in domestic supply for copper foils and necessary raw materials alongside CCL to maintain the competitiveness of locally produced PCBs to meet both national and international demands.