Courtesy: Siemens

The types of aircraft and spacecraft being flown are always changing, and in the last few years, especially, the world has witnessed the development of new, exciting ones. Innovations in electronics, software, autonomous flight, and launch systems for space have given rise to new classes of crafts that are much smaller and less expensive to make than traditional aerospace products, namely in the realms of drones and satellites. As a result, these crafts can be produced at higher volumes, a notable departure from the low-volume production typical of the industry.

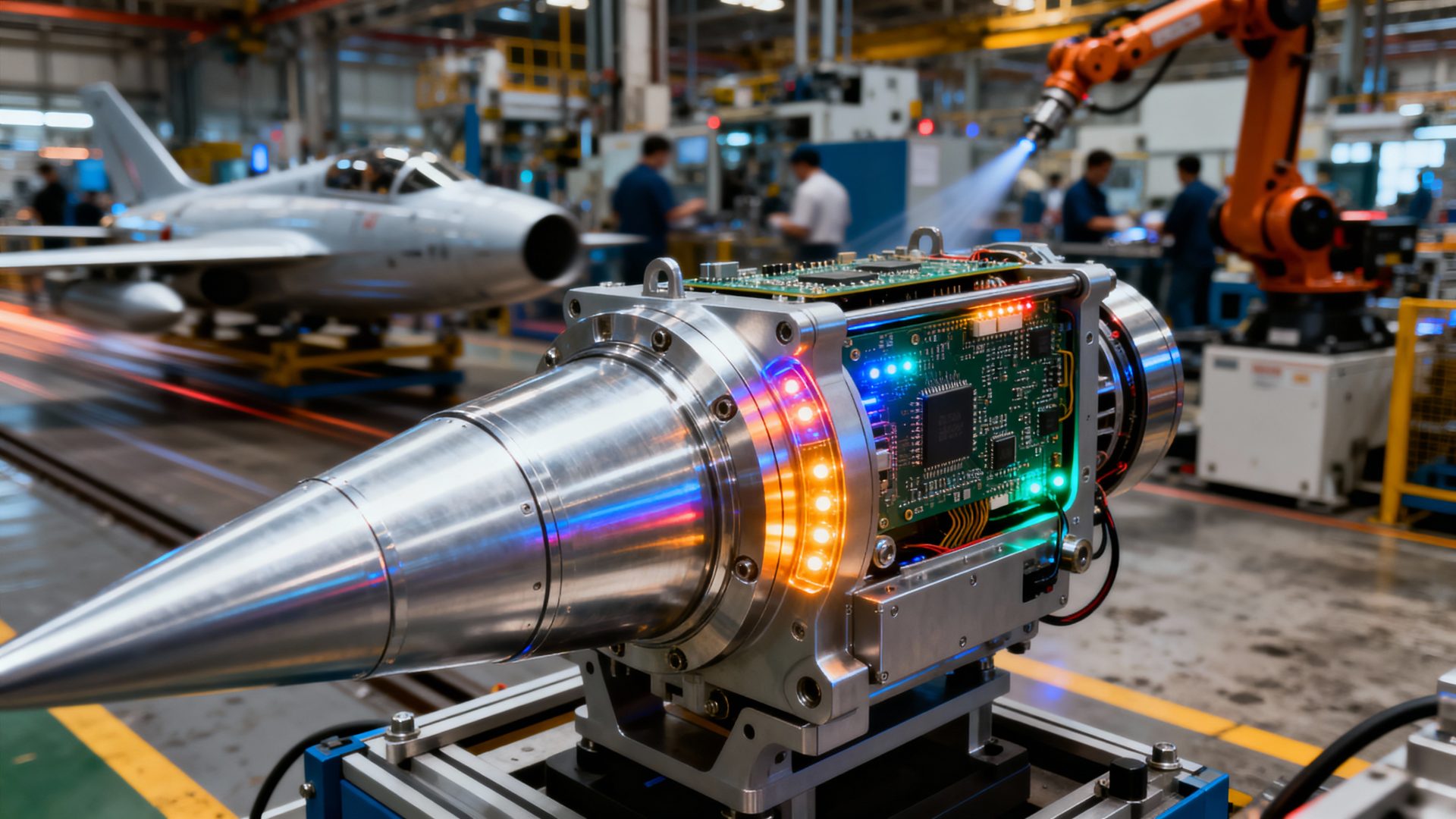

However, while aerospace products are ready to transform aviation and space exploration, there is still room for improvement in aerospace manufacturing processes. Technology and strategies such as robotics and automation have indeed been increasing efficiency in aerospace production processes, but many of those processes still rely on fixed tooling and human labour.

The answer lies not in technology alone, but also in the leveraging of data and digital transformation to build and optimise aerospace factories with interconnected data analytics and adaptive processes, or in other words, smart manufacturing. By integrating smart technology into their production processes, aerospace manufacturers can meet the higher production volumes in demand for new aircraft and spacecraft, ensuring their successful launch.

Empowered by data

Manufacturing in aerospace has certainly benefited from automation and robotics on the factory floor. Moving materials, machining parts, and additive manufacturing are among many tasks once operated by humans, now delegated to machines, increasing production rates while also decreasing the risk of injury for workers. To meet the desired production volumes for new aircraft and spacecraft, however, automation needs to take on more complex tasks. Yet such strategies can be expensive, and manufacturers want to make sure their implementation is not only successful but also yields a return on investment.

Smart manufacturing can help make this happen by utilising digital technology and tools to provide manufacturers with key insights into their production processes and ensure successful implementation.

One such foundational tool for this type of manufacturing is the comprehensive digital twin, the virtual representation of a product, process, or system across its entire lifecycle. In a manufacturing sense, the digital twin can replicate any process from an individual assembly line to an entire factory in a virtual space. Engineers can run this virtual version of their process through various simulations to test any changes or additions, and identify errors or areas for improvement before ever carrying out their operation physically. This can save enormous amounts of time and resources on new manufacturing strategies that would otherwise be spent correcting mistakes after implementation.

Optimized operation

Of course, smart manufacturing also has much to offer in the operation of production processes as well. The machines in a factory can be equipped with IT/OT sensors, monitoring the machines and providing real-time data analysis regarding their performance. Engineers can use this data to identify parts of the process that are underperforming, then feed the data into the comprehensive digital twin to provide more accurate simulations as they work to find a solution. With a constant stream of real-time data, the optimisation of aerospace manufacturing processes continues throughout their lifecycles.

Between innovations in aerospace systems and the rise of high-volume aircraft such as drones and satellites, the aerospace and defence industry is entering an exciting era. However, its manufacturing capabilities must be ready to support the industry to help meet the demands it is facing today. Fortunately, digital transformation and smart manufacturing can do just that, providing manufacturers with insights through simulation and data analysis to implement new manufacturing strategies and optimise them for years to come.