Innovations in Optics, Inc. offers LumiBright UV-LED Light Engines, powerful solid-state sources that are being used within OEM equipment applied to photocuring of adhesives and coatings as well as photomask exposure systems for photolithography.

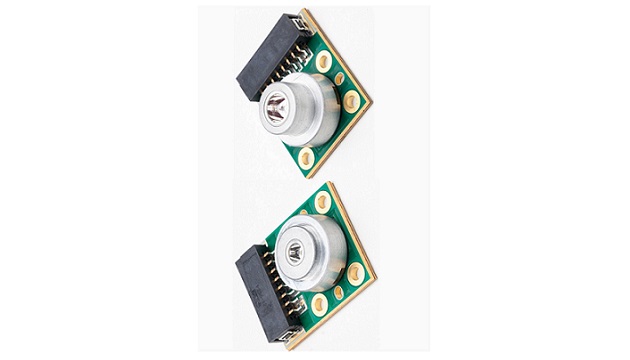

LumiBright UV-LED Light Engines feature UV die arrays bonded on MCPCB substrates that enhance thermal performance for high current density operation. The specialized primary optic is a non-imaging concentrator made from fused silica, ideal for high power UV flux. With active cooling, the model 2400B-405 model can emit greater than 20 Watts from a 7.5 mm diameter clear aperture with a 0.66 numerical aperture (NA). Model 2400B-505 light engine can produce over 10 Watts of radiant flux from a 5 mm diameter clear aperture with 0.60 NA. LumiBright UV-LED Light Engines are available with wavelengths centered near 365 nm, 385 nm, 395 nm, and 405 nm. For photolithography, 435 nm LEDs are also available.

For spot curing applications, LumiBright UV-LED Light Engines easily couple to liquid light guides for the ultraviolet. The clear apertures and NA of the 2400B-405 and 2400B-505 match the diameters and numerical aperture of typical liquid light guides. No additional optics are necessary since the light guide ferrule can be simply butt-coupled to the optical aperture of the LumiBright UV-LED Light Engines.

As a UV exposure source for photolithography, LumiBright UV-LED Light Engines offer economic and ecological advantages compared to traditional mercury arc lamps. The economic benefits originate from UV LEDs being more energy efficient, smaller in size and operating with consistent emission for very long lifetimes. Narrowband emission and instant-on capabilities limit heating to reduce exposure system cooling costs. Instantly stable illumination from UV-LEDs also eliminates daily calibration of exposure systems. Mercury lamps need several minutes to warm up, and therefore must remain on employing a mechanical shutter to control exposure time. The ecological benefits stem from the energy efficiency, and the fact that UV LEDs are mercury-free, generate no ozone and emit no harmful “deep UV” radiation.

For more information, visit: www.innovationsinoptics.com