Demand for wind power has grown and with it the need to inspect turbine blades and identify defects that may impact operational efficiency.

From visual thermography to ultrasound, a wide range of blade inspection techniques have been trialed, but all have displayed drawbacks.

Most inspection processes still require engineers to carry out manual examinations that involve capturing a large number of high-resolution images. Such inspections are not only time-consuming and impacted by light conditions, but they are also hazardous.

Computer scientists at Loughborough University have developed a new tool that uses artificial intelligence (AI) to analyze images of wind turbine blades to locate and highlight areas of defect.

And better yet, the system, which has received support and input from software solutions provider Ralston & Co Ltd, has been ‘trained’ to classify defects by types—such as crack, erosion, void, and ‘other’ – which has the potential to lead to faster and more appropriate responses.

The proposed tool can currently analyze images and videos captured from inspections that are carried out manually or with drones.

Future research will further explore using the AI tool with drones in a bid to eliminate the need for manual inspections.

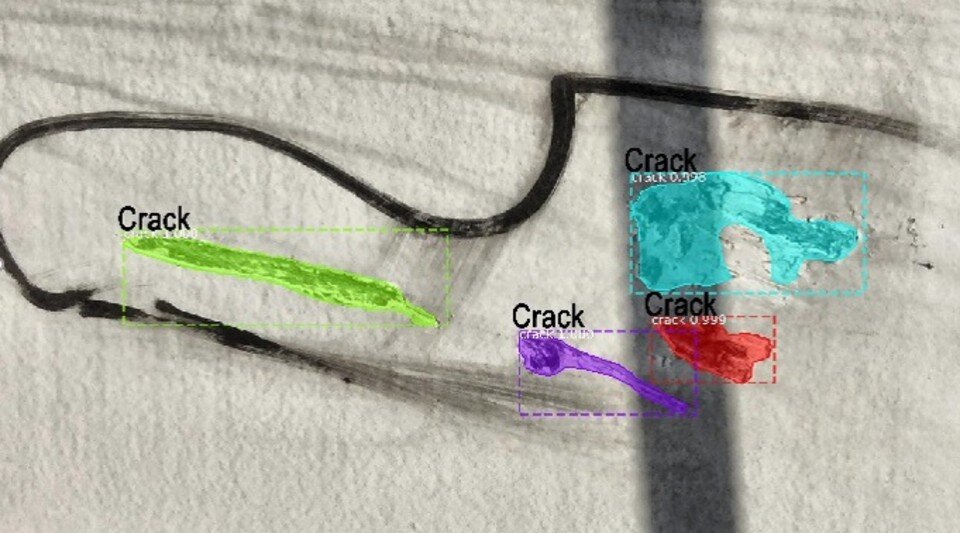

Using image enhancement and augmentation methods, and AI algorithms (namely the Mask R-CNN deep learning algorithm), the system analyses images then highlight defect areas and label them by type.

After developing the system, the researchers put it to the test by inputting 223 new images. The proposed tool achieved around 85% test accuracy for the task of recognizing and classifying wind turbine blade defects.

The paper also proposes a new set of measures for evaluating defect detection systems, which is much needed given AI-based defect detection and existing systems are still in their infancy.

AI is a powerful tool for defect detection and analysis, whether the defects are on wind turbine blades or other surfaces.

Using AI, we can automate the process of identifying and assessing damages, making better use of experts’ time and efforts.

Of course, to build AI models we need images that have been labeled by engineers, and Ralston & Co ltd are providing such images and expertise, making this project feasible.

Defect detection is a challenging task for AI since defects of the same type can vary in size and shape, and each image is captured in different conditions (e.g. light, shield, image temperature, etc.).

The images are pre-processed to enhance the AI-based detection process and currently, we are working on increasing accuracy further by exploring improvements to pre-processing the images and extending the AI algorithm.

AI has the potential to transform the world of industrial inspection and maintenance. As well as classifying the type of damage we are planning to develop new algorithms that will better detect the severity of the damage as well as the size and its location in space.

As well as further exploring how the tech can be used with drone inspections, the Loughborough experts plan to build on the research by training the system to detect the severity of defects. They are also hoping to evaluate the performance of the tool on other surfaces.