Overview

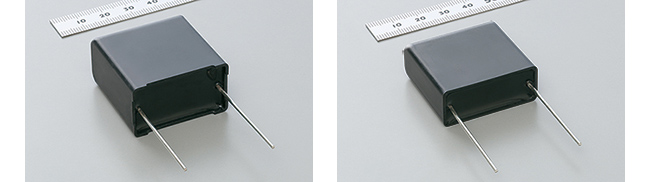

Murata has together with Shizuki Electric Co., Inc. (hereafter called “Shizuki Electric”) developed the FH series of heat-resistant film capacitors which can be used in a high-temperature environment of 125℃. These products are ideally suited for converters and motor drive inverters for environmentally friendly automobiles, or other applications requiring high-temperature performance.

Samples are scheduled to be available in September, with mass production beginning in April.

Background

There are increasing demands from manufacturers of hybrid vehicles, electric vehicles and environmentally friendly automobiles are increasing demands for electronic components that are compact, lightweight, and also have high dielectric capacitance and high heat resistance.

Capacitors used in converter and motor drive inverters are required to have a greater guarantee of high-temperature performance, than ever before, and also capacitors used in power supply lines are required to have a self-healing function. Generally, conventional high-temperature film capacitors were guaranteed to withstand temperatures of up to 105℃, and there were apprehensions to the effect that the self-healing function was not very reliable, resulting in the occurrence of short mode breakdowns.

Murata has recently developed new high-temperature film material, and together with Shizuki Electric developed the heat-resistance film capacitors for automotive applications, which can be used continuously in a high-temperature environment of 125℃ and also have a reliable self-healing function. As a result of this development, the new products can be used in a temperature zone where conventional film capacitors could not be previously used.

Product Specifications

- Ratings

Rated Capacitance:10,15, 20 μF

Rated Voltage:450 V - Reliability

High-temperature load: 125℃/ 450 V 2000 h

Humidity resistant load: 85℃ / 85% RH / 450 V 1000 h

Heat shock resistance: -40℃ ⇔ 125℃ 1000 cycles

For more information, visit www.murata.com