Advances in wearable devices have enabled E-Textiles, which fuse lightweight and comfortable textiles with smart electronics, and are garnering attention as the next-generation wearable technology. In particular, fiber electronic devices endowed with electrical properties, while retaining the specific characteristics of textiles, are key elements in manufacturing e-textiles.

Optoelectronic devices are generally constructed using layers of semiconductors, electrodes, and insulators; their performance is greatly affected by the size and structure of the electrodes. Fiber electronic components for e-textiles need to be fabricated on thin, pliable threads; since these devices cannot be wider than threads having diameter of a few micrometers, it is a challenge to improve the performances of such fiber electronic components. However, a team of Korean scientists has been receiving attention after developing a new technology to overcome these limitations.

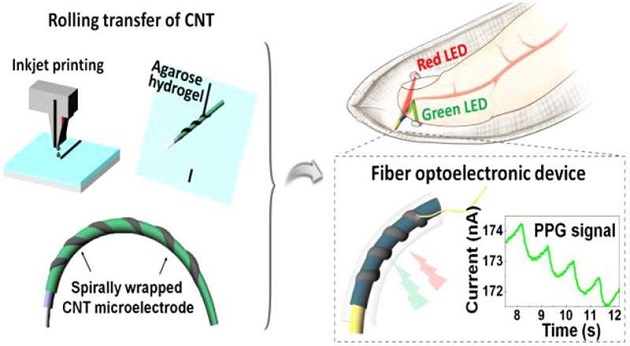

A team of researchers from the Korea Institute of Science and Technology (KIST) announced that they have developed a technique to manufacture fiber electronic components, such as transistors and photodiodes, with desired electrode structures by wrapping. Specifically, the desired electrode array can be fabricated using an inkjet printer, and an electrode thread coated with a semiconductor surface is rolled on top of these electrodes.

The research team developed a technique to build an electrode array on a given surface by printing carbon nanotube (CNT) ink on a template made of a hydrophilic hydrogel and transferring the CNT ink to the desired surface (Nano Letters 2019, 19, 3684-3691). Once printed on the hydrogel, the CNT electrodes behave in a manner similar to floating on water. Hence, the researchers predicted the possibility of transferring such electrodes intact to the surfaces of fibers by rolling the fibers on the electrodes. In a collaborative study with Dr. Lim and her team, the researchers were able to develop high-performance fiber electronic components without damaging the semiconductor layer or CNT electrodes. The fiber transistors wrapped with CNT electrodes maintained stable performances of at least 80% even with a sharp bend radius of 1.75 mm.

Using the semitransparent property of the CNT electrode, the researchers have also succeeded in developing fiber photodiodes to detect light by wrapping the CNT electrodes around electrode threads coated with a semiconductor that produces current upon absorption of light. The fiber photodiodes can detect a wide range of visible light and have excellent sensitivities that are comparable to those of rigid components. The researchers manufactured a glove from a fabric containing these photodiodes and light-emitting diodes (LEDs). The LEDs produce light, and the photodiodes measure the intensity of the light reflected by the fingers, which changes according to blood flow. Thus, the glove can be used to measure the wearer’s pulse.

The finger glove pulse monitor developed by us could offer an alternative to the conventional clip-type pulse monitoring device. It has the advantages of being more approachable for patients because of its comfortable and soft texture and of being able to measure the pulse in real-time in any time and place.