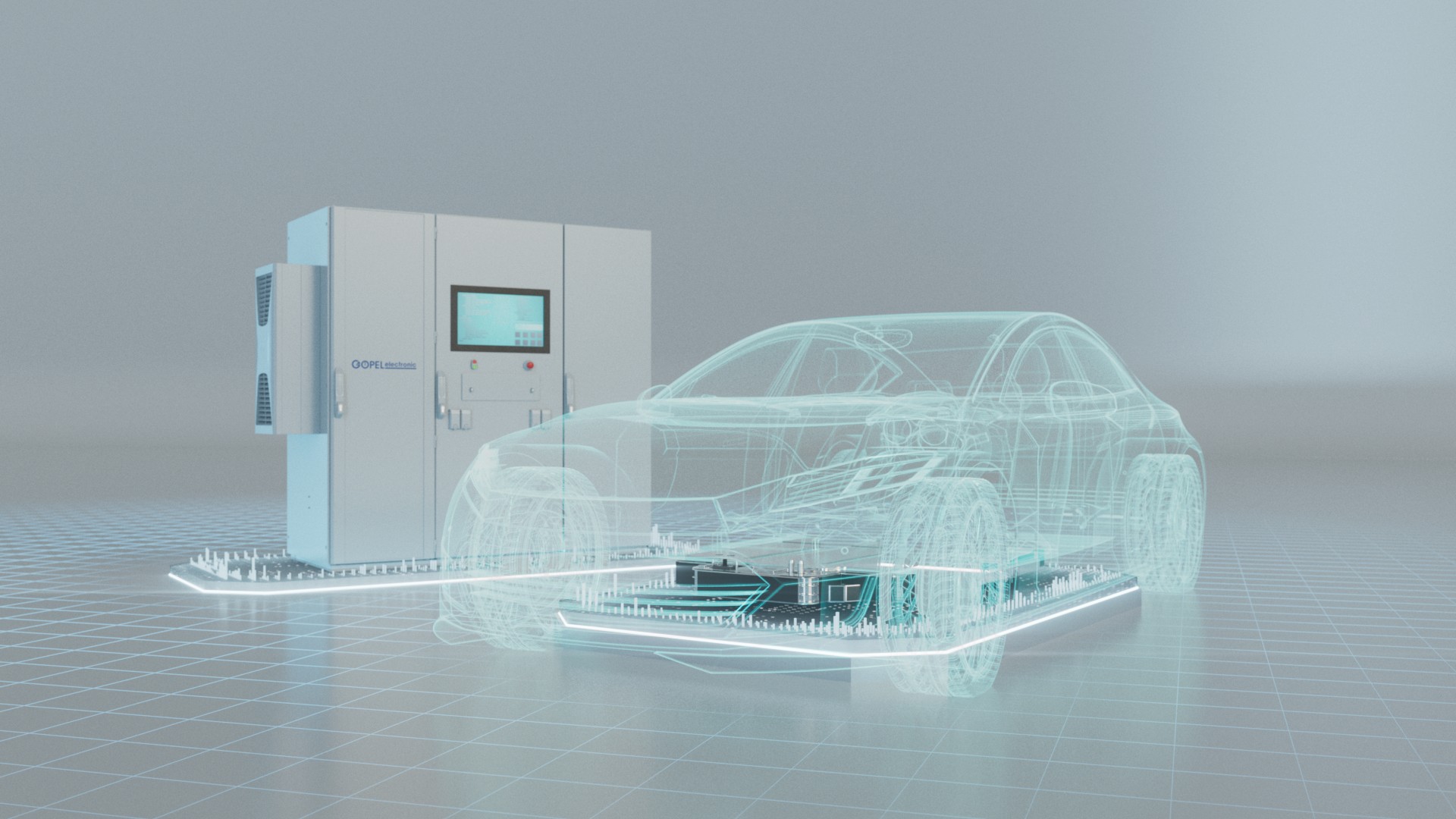

Cost-efficient electric car battery tests in automotive development and production

For fast quality testing of battery cells, GÖPEL electronic has developed a powerful and quickly configurable battery test bench that features a modular design and high flexibility. The system consists of a central measurement technology unit with a computer and monitor, a control cabinet, and a unit with all the power electronics, and can be adapted to the user’s needs in a modular fashion.

The battery test bench offers a power range up to 500 kW and tests in the voltage range up to 1,000 V DC with test currents of up to 800 A DC. Insulation tests can be performed with up to 7.5 kV. Thanks to its regenerative capability, the test solution is also designed to be highly energy-efficient. The scope of services includes safety tests and functional tests. These tests evaluate the condition of the cells, the impedance of the battery under alternating current, and the alternating current dynamics of the cell, and detect critical defects. The test results provide information about electrochemical processes in the cell, aging effects, and internal resistance fluctuations across different frequencies.

As part of the functional test, the GÖPEL electronic test system communicates with the battery management system (BMS) via CAN-BUS. The battery is charged with a prescribed and defined charging pulse, discharged, and finally the “state of charge” is checked. After the battery is discharged, the energy required for this is fed back into the power grid by the test solution, ensuring high energy efficiency and cost savings.

At the end of the security and functional tests, all test results are automatically exported to a database in the production department in individually configurable reports. Before delivery, the system checks the quiescent current to ensure that no unnecessary consumers can drain the battery. In addition, the desired state of charge is ensured, the final sensor data is read out, error memory entries are compared, and finally, the end customer software is flashed onto the battery.