By Sukhendu Deb Roy, Industry Consultant

Why India is uniquely positioned to lead the next electronics revolution by closing the loop between silicon, software, and the road?

Intro: India’s EV Electronics Moment

India is at a powerful inflection point: a fast-growing EV market, a strengthening semiconductor design ecosystem, and a deep pool of AI and software talent. The real value in this transition will not come from assembling more electric vehicles alone, but from mastering the chips, power electronics, and intelligence that make EVs reliable, safe, and always available.

From SiC traction inverters to battery management systems (BMS) and telematics ECUs, EV reliability is fundamentally an electronics problem that plays out under harsh, real-world Indian conditions. For OEMs and their Tier-1 and Tier-2 partners, this shift means semiconductor decisions, electronics architecture, and AI strategy are no longer separate silos; together they determine uptime, warranty risk, and customer trust.

AI can close the loop between semiconductor device behavior and field performance, turning today’s reactive maintenance into tomorrow’s predictive and self-healing EV ecosystems.

Takeaway: AI-powered semiconductor and EV electronics design can shift reliability from reactive repairs to predictive and self-healing systems, cutting failures, downtime, and warranty costs by roughly 40–60% over time — and India is uniquely placed to lead this shift.

From Semiconductor Device Design to EV Reliability

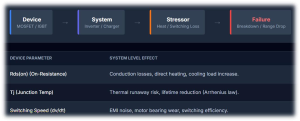

Every EV reliability story starts at the device level. Choices around Si/SiC MOSFET design, IGBT technology, gate-driver strategies, packaging, and thermal paths determine switching losses, heat, and long-term stress in traction inverters and onboard chargers. Under Indian duty cycles

— high ambient temperatures, stop-go traffic, overloaded vehicles, and poor roads — those design decisions show up later as derating, efficiency loss, or outright failures.

The same applies to battery cells and BMS hardware: cell chemistry, form factor, and sensing strategies determine how accurately the system can “see” degradation or thermal risk. When this visibility is poor, fleets experience unexpected range drops, thermal events, and a costly pattern of warranty claims and field fixes.

AI as a New Design and Reliability Loop

Traditional semiconductor and power-electronics design relies on simulations, design for reliability (DfR), lab validation, and field-return analysis. AI adds a new, continuous feedback loop: it learns from billions of switching events, thermal cycles, and usage profiles observed in real vehicles, and feeds that learning back into both device design and control algorithms.

This loop uses signals such as high-frequency waveforms, temperature gradients across modules, vibration signatures, and battery state-of-health (SoH) curves to identify stress patterns and precursors to failure. Over time, designers can co-optimize silicon, packaging, and firmware for actual Indian operating conditions rather than idealized lab scenarios — improving both first-time-right silicon and long-term field reliability.

A quick India scenario: Imagine a 2-wheeler fleet in Chennai. AI models trained on inverter waveforms and temperature data across thousands of rides can flag an emerging failure pattern in a particular batch of power modules and trigger an OTA-driven derating and firmware fix before riders see breakdowns.

Four AI Capabilities That Change EV Reliability

Predictive BMS Intelligence (Cell-level)

Batteries are the single largest cost item in EVs and one of the most reliability-critical. AI models can continuously learn from cell voltages, temperatures, internal resistance evolution, and charge–discharge histories to detect early degradation, thermal runaway risk, and balancing drift at cell level. For Indian conditions — high temperatures, frequent partial charging, and stop-start usage — such predictive BMS intelligence can extend usable battery life by double-digit percentages and materially improve safety. Better SoH and range estimation also reduce range anxiety for drivers and allow fleet operators to plan maintenance proactively.

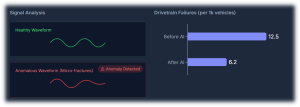

Inverter and Motor Diagnostics from Device-level Signals

Traction inverters and motors sit at the heart of EV performance, directly built on semiconductor device and magnetic design Machine-learning models can analyse switching waveforms, current and voltage harmonics, torque–speed behavior, vibration patterns, and thermal maps to catch subtle anomalies long before a fault triggers a visible error. This enables early detection of gate-drive misbehavior, partial shorts, insulation degradation, bearing wear, and cooling issues that would otherwise surface as roadside failures or derated power. At fleet scale, such diagnostics can realistically cut unexpected drivetrain failures by 30–50%, significantly improving asset utilization.

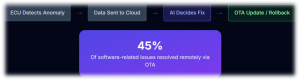

OTA-based Self-healing Firmware

Diagnostics alone are not enough; systems need a way to act on insights in the field. Over-the-air (OTA) firmware platforms, combined with AI, can detect abnormal behavior in ECUs, roll back to known-good images, patch vulnerabilities, and adjust control parameters to protect power devices and batteries. For example, if analytics indicate elevated stress on a particular inverter design in hot regions, OTA updates can modify switching patterns, current limits, or thermal thresholds to reduce risk without requiring a workshop visit. OEMs already see significant warranty and recall savings from OTA-based fixes; AI-guided self-healing will deepen this advantage and improve customer experience.

Fleet-level AI Learning Loop

The full power of AI emerges when every vehicle becomes a data node. Connected EVs stream anonymized health, usage, and environment data to the cloud, where AI aggregates patterns across cities, duty cycles, and seasons. Refined diagnostic and control models are then pushed back to vehicles via OTA, closing the loop from chip to cloud and back.

In this paradigm, EVs do not just age; they improve over time. Updated BMS models provide better SoH estimates, inverter control becomes more efficient, and fault detection grows more sensitive with every kilometer driven. The same hardware platform becomes more valuable with each software and model refresh — a powerful shift in how the industry thinks about lifecycle value.

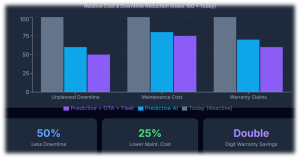

By the Numbers: Why 40–60% is Realistic

Evidence from other industries shows that AI-driven predictive maintenance can reduce unplanned downtime by about 30–50% and cut maintenance costs by 18–25% through earlier fault detection and better planning. At the same time, connected diagnostics and OTA capabilities allow OEMs to resolve many issues remotely, significantly lowering warranty and recall costs.

When these approaches are applied systematically across EV batteries, powertrain electronics, and software — and when semiconductor and system design are instrumented for rich telemetry — it is credible to target 40–60% improvements in reliability metrics and warranty economics over a multi-year horizon. This magnitude of impact justifies serious investment from OEMs, Tier-1s, Tier-2s, and policymakers.

What This Means for OEMs, Tier-1s, and Tier-2s

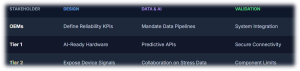

- OEMs

- Define EV reliability KPIs (uptime, failure rates, cost per vehicle) that explicitly depend on electronics and AI, not just mechanical systems.

- Mandate data pipelines, OTA capabilities, and diagnostic hooks as core requirements in platform and supplier specifications.

- Tier-1 suppliers (inverters, BMS, ECUs, telematics)

- Design hardware and firmware with AI-grade observability: rich sensing, timestamped logs, and secure connectivity interfaces.

- Offer OEMs diagnostics and predictive-maintenance APIs as part of the product, not as optional add-ons.

- Tier-2 and component suppliers (devices, sensors, boards)

- Expose relevant device-level health signals (e.g., temperature, switching counters, error events) that higher-level ECUs and cloud models can consume.

- Collaborate with Tier-1s on test data, stress conditions, and failure signatures to make AI models more accurate.

India’s Edge: From Design Hub to EV-AI IP Hub

India is already emerging as a major center for semiconductor design, verification, and R&D services, with global chip majors expanding their engineering presence in the country. Parallelly, the domestic EV market — particularly in 2-wheelers, 3-wheelers, and commercial fleets — is scaling rapidly, creating demanding real-world use cases that generate rich data for AI models.

This combination positions India to move beyond low-cost manufacturing and become a global hub for EV electronics intelligence, including:

- AI-optimized power device reference designs for SiC/IGBT

- Predictive and interpretable BMS/Inverter control

- Validated OTA/diagnostics platforms for fleet

These are exportable IP and platform plays that can serve global OEMs, not just domestic brands, while also anchoring higher-value electronics manufacturing within India.

What Industry Must Do Next

To capture this opportunity, India’s ecosystem needs alignment across six pillars:

- Semiconductor & power-device design: Build AI-ready telemetry and reliability sensing into devices and modules from the outset.

- Power-electronics & system integration: Architect inverters, BMS, and ECUs for rich observability and secure connectivity.

- Software-defined vehicle architectures: Treat data collection, model deployment, and OTA as first-class design goals, not afterthoughts.

- Secure-by-design engineering: Ensure that telematics, OTA, and data flows are robust against cyber threats.

- Validation & standards: Extend traditional validation with AI-driven test generation, digital twins, and continuous in-field learning loops.

- Interdisciplinary Talent Development: Fund research and training programs to explicitly create hybrid talent (e.g., AI engineers specializing in power electronics and thermal physics) required to bridge the gap between device design and fleet data.

If OEMs, Tier-1s, Tier-2s, chip companies, startups, and policymakers work together across these pillars, India can define the template for AI-powered semiconductor design and EV reliability — and, in doing so, help lead the next global electronics revolution.

Email: mailsukhendu@gmail.com

LinkedIn: Sukhendu Deb Roy