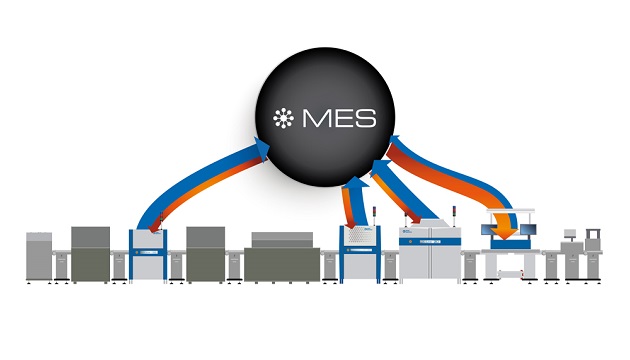

The connection to Manufacturing Execution Systems (MES) plays a central role in electronics manufacturing for efficient production control and as a data basis for recording and evaluating relevant data. Despite many efforts, no MES has been able to establish itself as a standard today, which means that a large number of systems exist.

New machines and production or inspection systems must therefore be individually adapted to the MES interface on the software side. This often takes up a lot of time and delays the complete integration of new systems in electronics production. The PILOT Connect software now ensures that the inspection systems from GÖPEL electronic are connected to the MES with the machine delivery.

GÖPEL electronic guarantees an integration of the respective AOI, AXI or SPI system into the MES infrastructure of the customer within a few weeks, at the latest with the installation of the system on-site at the user. Standard interfaces such as ZVEI, iTAC, Aegis, SECS/GEM, GEP, CAM and most recently IPC CFX are supported. Nevertheless, the systems can also interact with customer-specific MES solutions.

The fast connection is achieved by a sophisticated plug-in system of the GÖPEL electronic software PILOT Connect. With a ready-to-use framework the communication is realized by an own development team in exchange with the customer even at short notice. In addition, there is sufficient flexibility to respond to the individual wishes and requirements of electronics manufacturers.

In the PILOT Connect interface to the MES, data exchange takes place either on a pure result level (unidirectional), with product-specific control and process interlocking (bidirectional) or with production data acquisition. Extensive statistical evaluation options for all connected systems are available, as well as central repair or verification stations with display options for all inspection results involved. In addition to AOI, SPI or AXI systems from GÖPEL electronic, machines from other suppliers as well as electrical test systems can be integrated into PILOT Connect.

For more information, visit: www.goepel.com