Electric Vehicles (EVs), central to the global climate transition, are also becoming crucial drivers of engineering innovation. At the heart of this transformation lies the electric motor, an area now attracting intense R&D focus as automakers chase higher efficiency, lower material dependency, and superior driving performance.

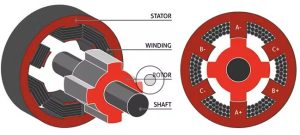

Conventional Motor Choices: IM, PMSM, and BLDC

Most EVs today rely on three key motor architectures:

- Induction Motors (IM): Rugged but less efficient.

- Permanent Magnet Synchronous Motors (PMSM): Highly efficient and used in high-performance vehicles.

- Brushless DC Motors (BLDC): Lightweight and ideal for scooters and bikes, using electronic commutation instead of brushes.

While these motors have served well, next-generation EV demands—compact packaging, higher power density, optimized cooling, and smarter control—are pushing the industry toward more advanced technologies.

What’s Driving the Next Wave of Motor Innovation

Manufacturers today are actively pursuing:

- Reduction in installation space

- Higher power-to-weight ratios

- Improved thermal management

- Lower reliance on rare-earth materials

- Greater efficiency through refined control electronics

These needs are shaping emerging motor technologies that promise major shifts in EV design.

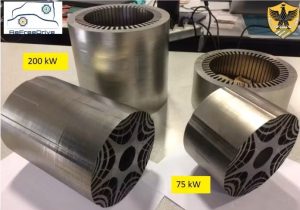

Axial Flux Motors: Compact Powerhouses of the Future

Axial flux motors—often called “pancake motors”—use disc-shaped stators and rotors. Unlike traditional radial flux machines, their magnetic field flows parallel to the shaft.

Key strengths:

- Extremely compact

- Exceptionally high power density

- Ideal for performance-focused EVs

A standout example is YASA, a Mercedes-owned company whose prototype axial flux motor delivers 550 kW (737 hp) at just 13.1 kg, achieving a record 42 kW/kg specific power.

Key challenge: Maintaining a uniform air gap is difficult due to strong magnetic attraction, making heat dissipation more demanding.

Switch Reluctance Motors (SRM): Simple, Strong, Magnet-Free

Switch reluctance motors operate using reluctance torque, relying solely on magnetic attraction rather than electromagnetic induction or permanent magnets. The rotor contains no windings or magnets, significantly reducing rare-earth dependence.

Advantages:

- Robust and simple construction

- Low material cost

- High torque potential

Companies like Enedym, Turnitude Technologies, and Advanced Electric Machines (AEM) are actively advancing SRM technology.

Challenges:

- High torque ripple

- Noise and vibration

- More complex control electronics due to trapezoidal DC waveforms

Increasing the number of stator/rotor teeth can reduce ripple but adds manufacturing complexity.

Synchronous Reluctance Motors (SynRM): Tackling Torque Ripple

SynRMs were developed to overcome the noise and vibration issues of SRMs. Their rotor design uses multiple layered air gaps, creating a shaped flux path that enhances torque production.

Key benefits:

- Operates on sinusoidal waveforms

- Much lower torque ripple

- No magnets required

- Improved noise characteristics

A well-known adaptation is seen in the Tesla Model 3, which uses a SynRM with internal segmented permanent magnets to reduce eddy-current losses and thermal buildup.

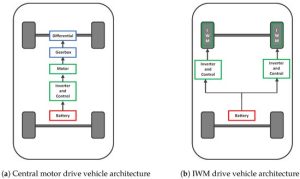

In-Wheel Motors: Reinventing Torque Delivery at the Wheels

In-wheel motor technology places a dedicated motor inside each wheel, eliminating conventional drivetrains.

Advantages:

- Increased interior space

- Reduced transmission losses

- Precise torque vectoring for improved handling

- Lower mechanical maintenance

GEM Motors, a Slovenian startup, has developed compact, modular in-wheel motor systems that claim up to 20% increased driving range without additional battery capacity.

Challenge:

In-wheel placement increases unsprung mass, affecting ride quality and requiring highly compact yet high-torque designs.

The Road Ahead: Designing Motors for a Resource-Constrained Future

With rising pressure on rare-earth supply chains and the push for higher efficiency, the next generation of EV motors must strike a balance between performance, sustainability, manufacturability, and cost. Technologies minimizing rare-earth usage, improving thermal robustness, and reducing weight will define the industry’s trajectory. As innovation accelerates, electric motors will not just power vehicles—they will shape the future of clean, intelligent, and resource-efficient mobility.