Electric vehicles (EVs) are no longer defined merely by battery size or driving range. At the very heart of their performance, efficiency, and intelligence lies the traction inverter a masterpiece of power electronics that converts DC from the battery into precise AC waveforms for motor drive.

What makes the inverter even more critical today is its evolution into a software-defined energy hub. Beyond simple power conversion, modern inverters integrate advanced semiconductors, AI-driven control, and bidirectional energy flow, turning EVs into smart, grid-ready assets.

Technologies Reshaping Inverter Design:

- Wide-Bandgap Semiconductors: SiC and GaN

- The transition from traditional silicon to wide-bandgap (WBG) materials such as Silicon Carbide (SiC) and Gallium Nitride (GaN) is revolutionizing inverter efficiency and compactness.

- SiC MOSFETs support high-voltage (up to 1200 V) operation, offer lower switching losses, and provide high thermal endurance. This enables smaller form factors, decreases cooling system requirements, and facilitates ultra-fast charging.

- GaN HEMTs are known for their high-frequency switching, which makes e-axles and multilevel inverter topologies more compact. They’re emerging in light EVs and auxiliary systems where space is at a premium.

These devices can achieve switching frequencies above 500 kHz, unlocking higher power density and smaller passive components. While SiC has already become standard in 800 V platforms, GaN is set to complement it in next-gen EV systems.

- AI-Based Predictive Control

In the realm of inverters, artificial intelligence is ushering in new operational paradigms. With Model Predictive Control (MPC) and machine learning at the helm, contemporary inverters:

- Mitigate torque ripple and switching losses

- Adapt in real-time to driving dynamics, component wear, and thermal conditions

- Support over-the-air (OTA) updates, ensuring inverter functionality is fine-tuned for the vehicle’s entire lifespan

Furthermore, AI-augmented control integrates perfectly with battery management and regenerative braking systems, facilitating enhanced, safer, energy-efficient driving.

- 800 V Architectures: Faster, Cooler, Smarter

- The industry’s shift to 800 V platforms marks a significant leap in EV capability:

- Enables 200–350 kW ultra-fast charging with minimal I²R losses

- Reduces cable thickness and weight, improving efficiency

- Achieves 10–15 min charging to 80% capacity

In such high-voltage environments, SiC-based inverters thrive achieving >98% efficiency while maintaining robust thermal stability.

- Bidirectional Energy Flow: Beyond Mobility

Modern traction inverters are designed for four-quadrant operation, unlocking multiple use cases:

- Vehicle-to-Grid (V2G): Supplying power back to the grid

- Vehicle-to-Home (V2H): Acting as an emergency or renewable energy backup

- Vehicle-to-Load (V2L): Powering tools or appliances on the go

These applications require adherence to global standards like IEEE 1547 and ISO 15118, alongside isolation and fault-tolerance mechanisms. In effect, EVs are becoming mobile energy storage units, supporting energy resilience and sustainability.

- Integrated E-Axle Designs

OEMs are increasingly adopting integrated e-axle solutions that combine inverter, motor, and gearbox in a single compact package. Benefits include:

- Reduced parasitics and cabling losses

- Shared cooling and thermal management

- Lower manufacturing complexity and cost

This architecture improves torque density and space efficiency—ideal for both urban EVs and high-performance electric sports cars.

- Modular Inverter Architectures

Scalability is key for automakers producing EVs across different segments. Modular inverter platforms allow:

- Power scaling from 75 kW to 300 kW

- Reuse of software, control logic, and digital stages

- Faster time-to-market and lower R&D costs

This flexibility helps OEMs deploy multi-platform strategies, from two-wheelers to heavy-duty trucks, with automotive-grade reliability.

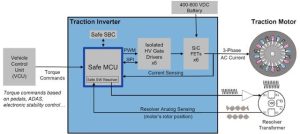

EV Traction Inverter Architecture:

Block diagram of an EV traction inverter system showing torque command flow from VCU to traction motor via Safe MCU, SiC FETs, gate drivers, and resolver-based feedback.

This diagram illustrates how torque commands from the Vehicle Control Unit (VCU) are processed by a safety-optimized microcontroller (Safe MCU), which drives high-voltage SiC FETs through isolated gate drivers. These switches convert DC from the battery into 3-phase AC for the traction motor. Resolver and current sensing provide real-time feedback, enabling precise motor control and efficient bidirectional energy flow.

System-Level Trends:

Beyond materials, traction inverter innovation is increasingly system-driven:

- Bidirectional Charging & V2G: SiC and GaN enable energy flow back to the grid, turning EVs into mobile storage units

- Integrated Powertrains: OEMs are combining inverter, motor, and gearbox into unified modules for space and weight savings

- Cooling Innovations: Double-sided cooling and optimized thermal paths are reducing module size and improving reliability

- Software-Defined Inverters: Adaptive control algorithms are enhancing efficiency across driving conditions

Industry Spotlight: Infineon Technologies

To understand how traction inverter technology is evolving in the EV sector, Hans Adlkofer, Senior Vice President of Automotive Systems at Infineon Technologies AG, shares his perspective. He explains the technological shifts driving more efficient, compact, and bidirectional inverters, and how these advancements are shaping the future of electric powertrains.

“We can expect even more compact and efficient traction inverter designs. The shift from traditional IGBTs to Silicon Carbide (SiC) is driven by the need for higher performance, reduced size, and increased EV range. Fusion of IGBT and SiC technologies in a single module also optimizes cost-performance. Gallium Nitride (GaN) will further support advanced inverter topologies, including multi-level designs.”

“The transition to SiC and GaN opens the space for innovative module development, such as smaller or optimized cooled modules. Discrete solutions allow very compact inverter designs or integration directly into the motor. This contributes to higher efficiency, lower cost, and increased mileage.”

“Latest SiC and GaN products enable bidirectional charging, supporting intelligent V2G use cases. EVs can now act as mobile energy storage units, creating a more sustainable energy ecosystem and new business models for battery utilization.”

Conclusion:

Traction inverters are no longer functioning solely to change DC to AC traction inverters have effectively become the brain centre of an electric vehicle’s power train. They are changing electric vehicle performance and energy management with wide-band gap semiconductors, AI predictive control, modular system designs, and energy flow that is bidirectional.

As automakers focus on increasing charging speed, boosting range, and developing more intelligent energy systems, traction inverters will be instrumental in the renaissance of electric vehicles.