As the nation gears up for the Union Budget 2026, slated to be presented in Parliament on February 1, electronics industry associations are stepping up efforts to push India’s electronics manufacturing ecosystem to its next phase of growth.

Among the key recommendations, the Electronic Industries Association of India (ELCINA) has proposed the establishment of 10 world-class, product-specific Electronics Manufacturing Zones (EMCs). The association has urged the government to upgrade the existing EMC 1.0 and EMC 2.0 cluster models to globally accepted infrastructure standards. According to ELCINA, such an approach would help ensure regional balance, improve local facilitation, and enhance India’s competitiveness and export potential.

Strengthening the manufacturing value chain further, the India Cellular & Electronics Association (ICEA) has recommended a reduction in customs duty on microphone, receiver, and speaker assemblies for mobile phones from the current 15% to 10%. The association believes that this duty rationalisation would create cumulative cost advantages, improve global competitiveness, and encourage additional investments in domestic component manufacturing.

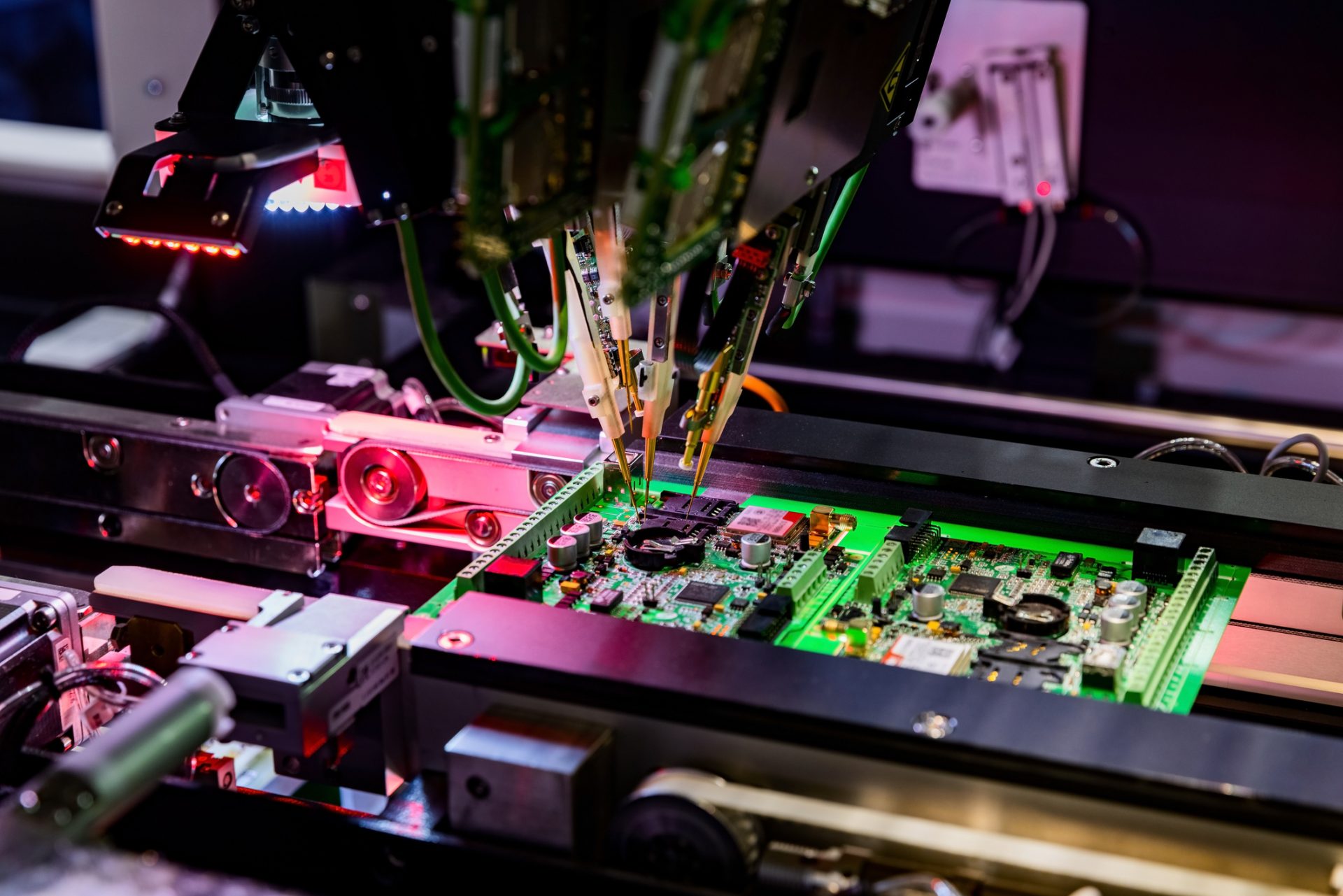

ICEA has also suggested reducing duties on Printed Circuit Board Assemblies (PCBAs) and Flexible PCB Assemblies (FPCAs) from 15% to 10%, a move aimed at supporting localisation and scale in electronics production.

Testing & Certification

For any industry, standards play a major role, whether for exports or inbound use; without certification, no product can see the light of day. Recognising this to be at the forefront of product development, ELCINA recommends introducing a Testing & Certification Support Scheme to provide financial support or reimbursement of testing and certification charges to MSMEs.

Also, to make the services accessible for small entities with minimal investments, the body recommends establishing regional accredited testing centers in collaboration with private labs, industry associations, and technical institutions as per BIS and other international standards. This would successfully ensure one of the vitals for strengthening the domestic manufacturing and R&D ecosystem.

Investment Fund for SMEs

As the Union Budget 2026 approaches, ELCINA has also highlighted the long-standing challenge of limited access to low-cost finance for SMEs in the electronics system design and manufacturing (ESDM) sector, noting that funding constraints continue to hamper their ability to scale and invest in advanced technologies. To address this, the association has recommended the creation of a dedicated Technology Acquisition Fund to support technology transfer and licensing, enabling Indian firms to move up the value chain and transition towards a product-led ecosystem.

ELCINA has also proposed a professionally managed, government-backed venture fund to support high-value-added manufacturing in electronic components, PCBs, and modules, along with targeted tax incentives, including investment- and dividend-stage exemptions for at least five years, to attract private equity and high-net-worth investors and help build globally competitive Indian champions.

Classification of Displays

In the same vein, the India Cellular and Electronics Association (ICEA) has raised concerns over the lack of clarity in the customs classification of display assemblies used across automobiles, medical devices, industrial electronics, and other applications. Although these displays are technologically identical to flat panel display modules used in mobile phones and televisions, they are often classified under different HSN codes based on end-use, resulting in inconsistent customs treatment and operational uncertainty across field formations.

To address this, ICEA has recommended uniform classification of all display assemblies under HSN 8524, regardless of application, a step it says would ensure global alignment, reduce classification disputes, and enable smoother integration of display manufacturing across product segments as domestic capacity scales up under the Electronics Components and Manufacturing Scheme (ECMS).

Conclusively, the industry’s pre-Budget recommendations point to a clear priority: strengthening India’s electronics manufacturing depth through targeted policy, fiscal, and regulatory interventions. With focused action on infrastructure, duties, finance, and classification clarity, Budget 2026 has the opportunity to accelerate India’s shift from assembly-led growth to globally competitive electronics manufacturing.