ASMPT presents central platform for data exchange in electronics manufacturing.

“WORKS Integration ensures that all production data is available exactly where it is needed for things like production planning and setup preparation, material flow and process optimization, and quality control,” said Thomas Bliem, Vice President R&D at ASMPT SMT Solutions. “By creating a centrally networked database with high connectivity across all systems, the platform makes fully digitized and highly automated intelligent production possible.”

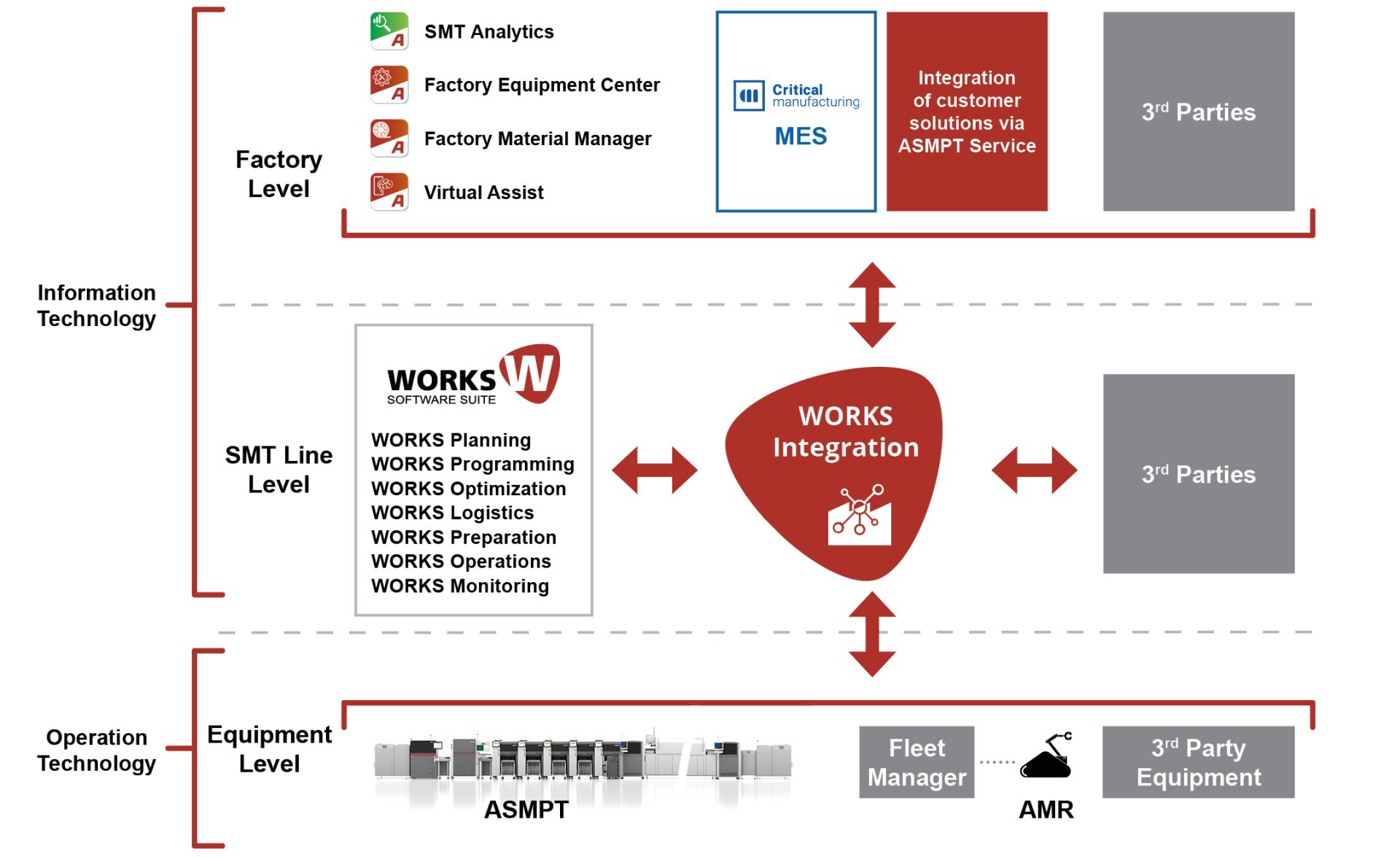

A central data hub for all systems

Extending across all protocols and versions, WORKS Integration establishes an IIoT communication base to which the sensors on the production hardware as well as all software applications send their data. In addition to connecting the entire hardware and software portfolio of ASMPT SMT Solutions, WORKS Integration makes it possible to integrate third-party machines and programs via industry-standard interfaces. Even complex customer-specific applications can be easily linked via proprietary interfaces.

All connected systems obtain the information they need exclusively via WORKS Integration. Operating in the background, the application enables the continuous exchange of data between different hardware and software entities irrespective of their format or manufacturer.

WORKS Integration supports proven internal machine interfaces as well as industry standards such as IPC-2591, CFX, and SECS/GEM. Adapters convert all incoming information into a shared public data structure.

Centralized, standardized, resilient

This unified system offers numerous advantages for users. Since the various instances do not communicate with each other directly but exclusively through WORKS Integration, the number of interfaces and data channels is reduced considerably, as are potential interdependencies and sources of errors.

Machines and/or programs can be easily replaced, updated and scaled up or down without creating version conflicts or redundant data streams while encrypted communication reliably protects the system from unauthorized access. In addition, a central health monitoring system provides valuable information for technical support and fault analysis.