One of the natal and most crucial stages of electronic devices’ production is the design stage. It encompasses the creative, manual, and technical facets incorporated in an electronic device. The design stage allows manufacturers and developers to convert a textual system definition into a detailed and functional prototype before mass production. Almost all the functional requirements of an electronic device are addressed at the design stage itself.

Considering the BOM and the DFM are crucial at this stage to maintain or improve quality,

while keeping a check on the cost and expected features and performance.

Fundamentals of the Design Process

- Prior to investing in materials required for manufacturing, it is essential to establish a

list of requirements. This helps the manufacturer understand the features required in

the product. Similarly, it is essential to conduct a thorough market research to identify

market gaps and consumer requirements to develop products that can address the

consumer needs. A successful product is one that fulfills what the market of similar

products lack. - Subsequently, after the conceptualization is complete, the focus shifts to creating a

design proposal and project plan. This defines the projected expenses involved in the

manufacturing process, an approximate timeline, along with other design and

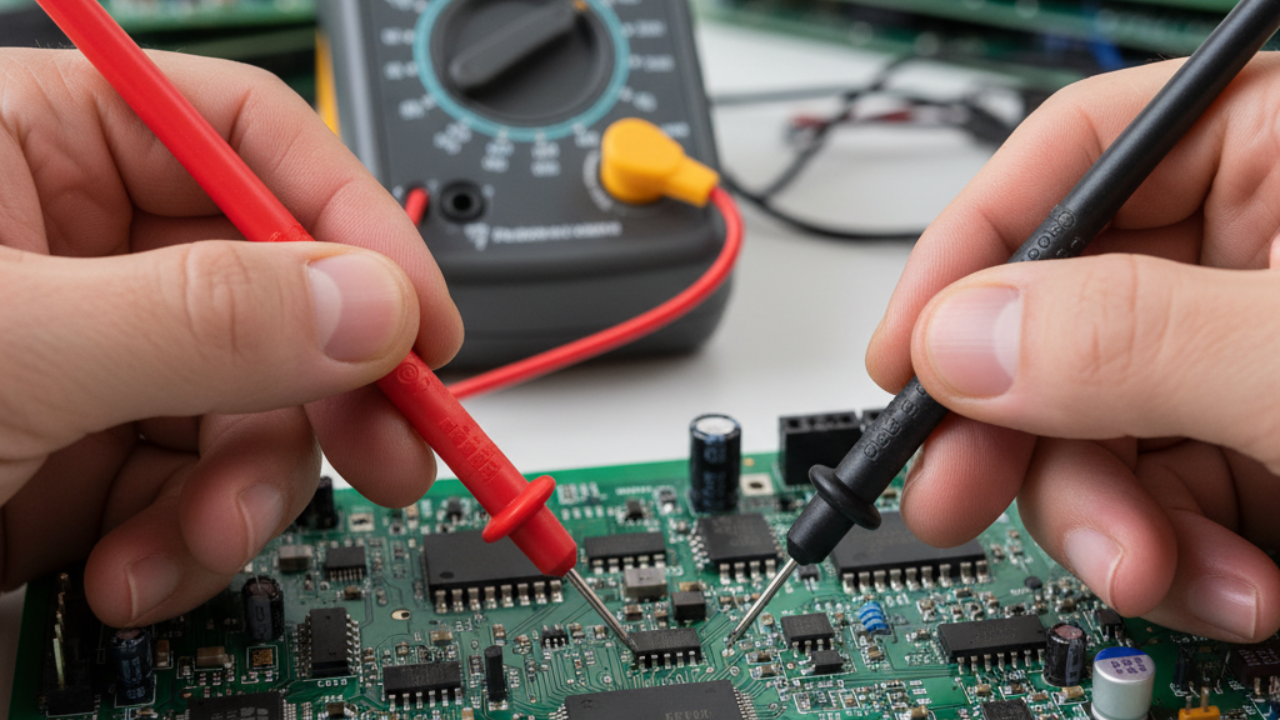

manufacturing process segments. - A final electronic device comprises of several small components like multiple

microcontrollers, displays, sensors, and memory to name a few. The advent in

technology has allowed us to leverage the usage of advanced software like Electronic

Computer-aided design (ECAD) or Electronic Design Automation (EDA) tools to

create the schematic diagram. These help in reducing the scope of error and act as

catalysts to the design process. - Eventually, the detailed schematic design proves beneficial for the next step where the

schematic is transformed into a PCB layout.

Growing Trends in the Design Process

- The advancement in nanotechnology and microfabrication techniques have evolved

the design process to allow for further miniaturization with increased integration on

chips. Design engineers can now add more features than before on a single chip along

with reducing its size. - Present day electronic designs are trying to incorporate the usage of renewable energy

as the industry shifts from fossil fuels. This change has forced designers to maneuver

the design of electronic devices along with incorporating advanced features like IoT

efficiency. - The growing demand for sustainable devices has equally affected the design process

which now needs to include features to reduce greenhouse gas emissions as well as

reduce energy consumption. This has influenced electric designers to modify power

converters and motor drives to reduce energy loss and increase efficiency. - The contemporary times also require the integration of automation and robotics for

both industrial and consumer electronic devices. The design process hence, has to assimilate these requirements to maintain the longevity of the electronic device to

allow its easy adoption of advanced technology. The same goes for integration with

artificial intelligence, a growing rage and one that is bound to prove monumental in

the simplification of the process and usage of electronic devices. - The major challenge in the design process is not the integration of such features but

their human-friendly integration. Any feature in a device can fail to fulfil its purpose

if it is not user-friendly, hence, the task falls on design engineers to make their access

easy and durable. - Apart from the features and structural innovation, the design process in upcoming

electronic devices has also undergone a change in the materials used. Newer, flexible

devices have changed the dynamics from rigid circuit boards to flexible substrates and

conductive polymers. Electronic designers are now compelled to adhere to even

mechanical flexibility in their electronic layouts.

Simplifying the Process for Complex Designs

As the need for miniaturisation and integration grows, the complexity of the design follows

suit, however, advancements in software and applications have simplified the process,

allowing designers to experiment with more creative ideas without compromising on the

timeline and costs.

While ECAD is one such innovation which has been adopted extensively now, some other

EDA tools are:-

- SPICE: This is a simulation tool used to analyse and predict the circuit's behaviour

under different conditions before building a physical prototype. It helps, identify and

fix potential issues in advance. - OptSim: This software tool allows designers to evaluate and optimize the

performance of optical links within a sensor design, predicting how light will behave

through components like lenses, fibres, and detectors.

Conclusion

Designing for electronic devices is a dynamic process and requires engineers to stay up-to-

date with the industry and market trends. As automation, robotics, and artificial intelligence garner a strong hold among electronics, their integration for the design process is inevitable. The design process is that vital and non-linear stage in manufacturing which often continues even post testing for refinement and then for documentation and certification.