Brain-inspired computing is a promising candidate for next-generation computing technologies. Developing next-generation advanced artificial intelligence (AI) systems that can be as energy-efficient, lightweight, and adaptable as the human brain has attracted significant interest.

“However, mimicking the brain’s neuroplasticity, which is the ability to change a neural network connection, in traditional artificial synapses using ultralow energy is extremely challenging,” said Desmond Loke, assistant professor at the Singapore University of Technology and Design (SUTD).

An artificial synapse—comprising a gap across two neurons to allow electrical signals to pass and communicate with each other—can emulate the efficient neural signal transmission and memory formation process of the brain.

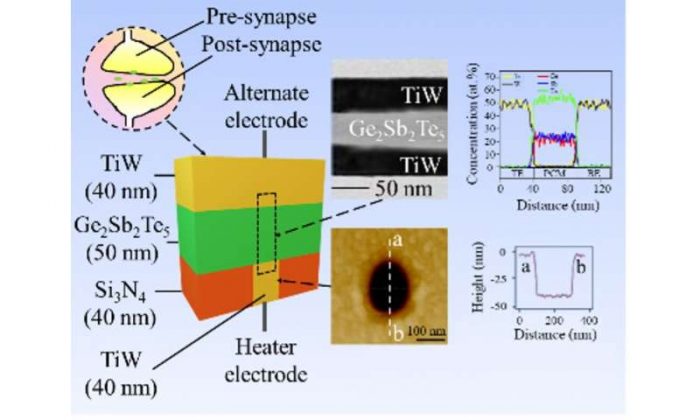

To improve the energy efficiency of the artificial synapse, Loke’s research team has introduced a nanoscale deposit-only-metal-electrode fabrication process for artificial synapse for the first time. By using deposit-only nanopillar-based germanium-antimony-telluride memristive devices, the team designed a phase-change artificial synaptic device that has achieved an all-time-low energy consumption of 1.8 pJ per pair-pulse-based synaptic event. This is about 82% smaller compared to traditional artificial synapses.

“The experiments have demonstrated that the artificial synapse based on phase-change materials could perform pair-pulse facilitation/depression, long-term potentiation/depression, and spike-timing-dependent plasticity with ultralow energies. We believe our finding can provide a promising approach for developing faster, larger scale artificial synapse arrays with significantly improved performance in AI tasks,” said Loke.

Traditional heater electrodes formed by the deposited and etched process can cause/create a large degree of damage at the interfaces. Alternatively, the heater electrodes created by a deposit-only process in this study could create a smaller degree of damage at the interface. This may lead to a more robust, defect-free interface with substantially decreased contact resistance and its variations, consequently resulting in decreased operating current.